The Role of Ball Valve Components in Industrial Systems

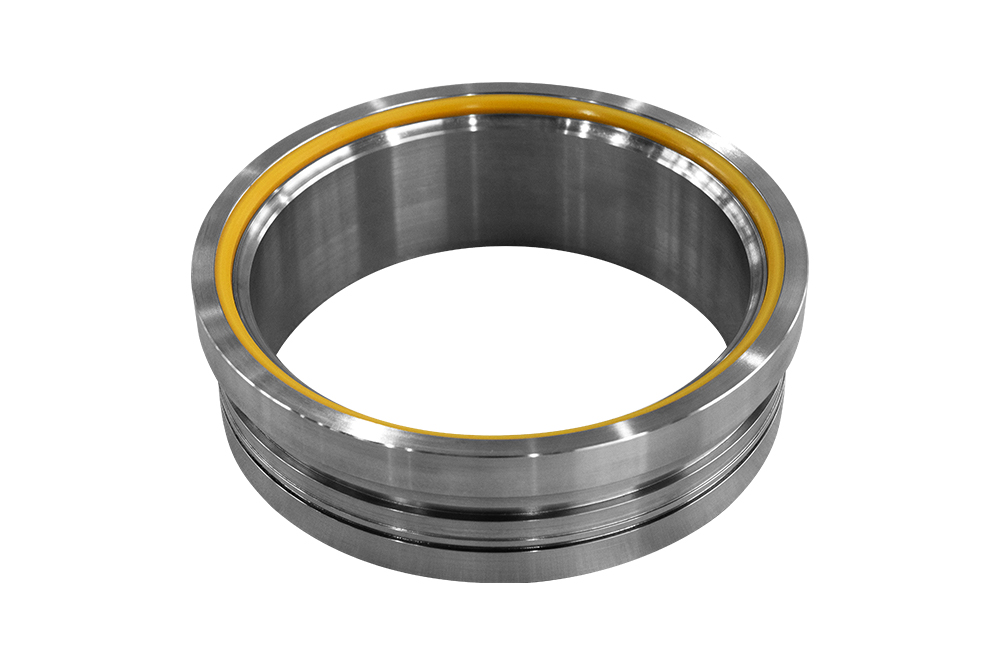

Ball valves are widely used in various industrial applications to control the flow of liquids and gases. The key components of a ball valve include the valve body, stem, seals, and the ball for valve—a spherical element that regulates flow by rotating within the valve housing. The design and material choice of these components directly impact the valve’s durability, sealing capability, and environmental impact.

For specific applications such as vacuum systems, the high vacuum ball valve plays a critical role in maintaining the integrity of the system by preventing leaks and contamination. These valves are engineered to function effectively under very low-pressure conditions, which requires precise manufacturing and materials that can withstand harsh operating environments.

Environmental Regulations Affecting Ball Valve Components

Various environmental regulations influence the production, materials, and disposal of ball valve components. Regulations often focus on reducing hazardous substances, controlling emissions, and promoting recycling and sustainability within the manufacturing process.

One key area of regulation concerns the use of materials that may be harmful to the environment or human health. Manufacturers are required to avoid substances like arsenic, mercury, cadmium, and certain phthalates in their products. This requirement affects the materials used to produce the ball for valve and other components, pushing the industry towards more environmentally friendly alloys and polymers.

Additionally, regulations targeting volatile organic compounds (VOCs) emissions during production encourage manufacturers to adopt cleaner processes. VOCs can be released during coating, painting, or sealing operations related to valve components. Controlling these emissions reduces air pollution and improves workplace safety.

Impact on Design and Manufacturing

To comply with environmental regulations, manufacturers of ball valve components must carefully select materials and production methods. For example, the ball for valve in high vacuum ball valves is often made from stainless steel or other alloys that provide corrosion resistance without relying on coatings or chemicals that contain regulated substances.

The design process also incorporates considerations for less waste and enabling easier recycling. Valve components that can be disassembled and sorted by material type support recycling efforts and reduce landfill waste.

Moreover, production facilities often implement environmental management systems to monitor energy consumption, waste disposal, and emissions. These systems help ensure that manufacturing practices meet regulatory standards and contribute to reducing the overall environmental footprint of ball valve components.

High Vacuum Ball Valve Specific Challenges

High vacuum ball valves face particular challenges in environmental compliance because of their specialized application. These valves must maintain an ultra-tight seal to prevent air or contaminants from entering the vacuum system. This requires precision engineering and high-quality materials that do not outgas or degrade over time.

Outgassing, the release of trapped gases from materials, is a significant concern in vacuum applications. Materials used in high vacuum ball valve components must be selected to less outgassing, which can compromise vacuum integrity and potentially cause environmental contamination.

Furthermore, cleaning and assembly processes for these valves must avoid the use of solvents or chemicals that could harm the environment or violate regulations. Manufacturers often employ water-based cleaning solutions or other environmentally friendly alternatives.

Compliance Benefits for Users and Manufacturers

For manufacturers, compliance with environmental regulations helps avoid legal penalties and can improve operational efficiency. Adopting greener materials and processes often advances to reduced waste and energy costs, supporting more sustainable production.

Users of ball valve components also benefit from compliance. Valves that meet environmental standards typically exhibit longer service life and safer operation, which reduces downtime and maintenance needs. In addition, companies that prioritize regulatory compliance may improve their reputation and strengthen relationships with customers who value sustainability.

Ball valve components, including the critical ball for valve and specialized high vacuum ball valves, must meet evolving environmental regulations. These regulations impact material selection, manufacturing processes, and product design to promote sustainability and reduce environmental harm.

Manufacturers who align their production with regulatory requirements contribute to safer industrial environments and support global efforts toward sustainable development. As environmental regulations continue to evolve, ongoing attention to compliance will remain a key aspect of producing reliable and responsible ball valve components.