Ball valves play a crucial role in controlling fluid flow across various industries, from oil and gas to water treatment and chemical processing. The demand for reliable and durable ball valves has driven continuous improvements in manufacturing processes. However, producing an ideal ball valve that meets performance, safety, and longevity requirements remains challenging. This article explores some common challenges faced in ball valve manufacturing and practical approaches to overcoming them, with a focus on the production and assembly of ball valve internal parts.

Challenge 1: Material Selection and Quality Control

One of the earliest and more critical challenges in ball valve manufacturing is selecting appropriate materials. The choice of metals, plastics, and sealing compounds directly impacts the valve's durability, resistance to corrosion, and suitability for specific applications. Variations in raw material quality can cause premature wear or failure during service.

Solution:

Implementing rigorous incoming material inspection and working closely with trusted suppliers helps maintain consistent material quality. Additionally, using materials that meet industry standards and certification requirements reduces the risk of product defects. For example, stainless steel grades that resist corrosion in harsh environments or high-performance polymers for sealing surfaces can extend valve lifespan.

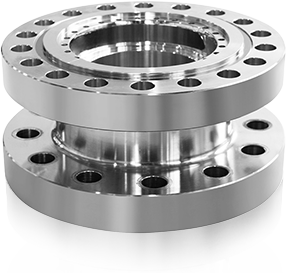

Challenge 2: Precision Machining of Ball Valve Internal Parts

The internal parts of a ball valve, such as the ball, stem, seats, and seals, require precise machining to ensure tight sealing and smooth operation. Manufacturing tolerances must be closely controlled to avoid leakage and operational issues. However, achieving the required precision can be difficult due to equipment limitations, tool wear, and human error.

Solution:

Utilizing CNC machining centers with advanced control systems enables higher accuracy and repeatability in manufacturing ball valve internal parts. Regular calibration and maintenance of machinery, along with thorough training for operators, results in fewer errors. Moreover, employing quality control techniques such as coordinate measuring machines (CMM) during production can identify deviations early, preventing defective parts from proceeding further in the assembly process.

Challenge 3: Ensuring Proper Sealing and Leak Prevention

Sealing performance is vital for ball valves, especially in applications involving hazardous or high-pressure fluids. The interface between the ball and valve seats must be free from defects, and sealing materials must be compatible with the media to prevent leaks. Manufacturing challenges include the risk of damage during assembly, wear of sealing components, and improper surface finishes.

Solution:

Advanced surface finishing processes, such as lapping or polishing, improve the sealing surfaces on the ball and seats, reducing friction and enhancing leak tightness. Selecting sealing materials based on the chemical and thermal environment helps maintain seal integrity over time. Automated assembly lines with controlled torque application prevent damage to seals during installation. Testing protocols, including pressure and leak tests on assembled valves, confirm sealing effectiveness before shipment.

Challenge 4: Assembly Complexity and Consistency

The assembly of ball valve internal parts must be precise and repeatable to ensure reliable valve operation. Complexity arises from the number of components involved and the need for correct alignment and torque settings. Inconsistent assembly practices can advance to functional defects such as sticking stems, improper sealing, or premature wear.

Solution:

Developing detailed assembly instructions and standardized procedures ensures consistency across production batches. Automation and the use of torque-controlled tools help apply precise forces to fasteners and components. Training assembly staff on the importance of each step and inspection checkpoints prevents errors. Conducting functional tests such as operational torque measurement and cycle testing can validate assembly quality.

Challenge 5: Managing Production Costs While Maintaining Quality

Manufacturers face constant pressure to reduce costs without compromising product quality. The complexity of ball valve design and strict performance requirements often advance to higher production expenses. Balancing cost control with quality assurance presents a continual challenge.

Solution:

Adopting lean manufacturing principles helps eliminate waste and improve efficiency. Optimizing production workflows, less material scrap, and reducing setup times contribute to cost savings. Investing in automation where appropriate can increase throughput while maintaining precision. Collaborating with material suppliers for bulk purchasing or exploring alternative materials that meet standards at lower costs also supports cost management.

Challenge 6: Meeting Diverse Industry Standards and Regulations

Ball valves are used across many industries, each with its own set of regulatory requirements and standards. Compliance with pressure ratings, fire safety, chemical resistance, and environmental regulations adds complexity to the design and manufacturing process. Non-compliance risks product rejection and liability.

Solution:

Staying informed about relevant industry standards and updating manufacturing processes accordingly is essential. Documenting compliance through testing and certification demonstrates adherence to regulations. Designing modular valve components allows customization to meet specific industry demands without extensive redesign.

Manufacturing an ideal ball valve involves overcoming multiple technical and operational challenges. From material selection and precision machining of ball valve internal parts to assembly consistency and regulatory compliance, each stage demands careful attention and continuous improvement. By adopting advanced technologies, standardized processes, and thorough quality control measures, manufacturers can produce ball valves that meet the diverse needs of industrial applications, ensuring reliability and customer satisfaction.