The manufacturing of ball valve components has seen significant changes in recent years due to advances in automation technology. Automation is reshaping how precision ball valve parts and high pressure brass ball valve components are produced, improving efficiency, consistency, and quality while addressing the challenges faced in traditional manufacturing processes.

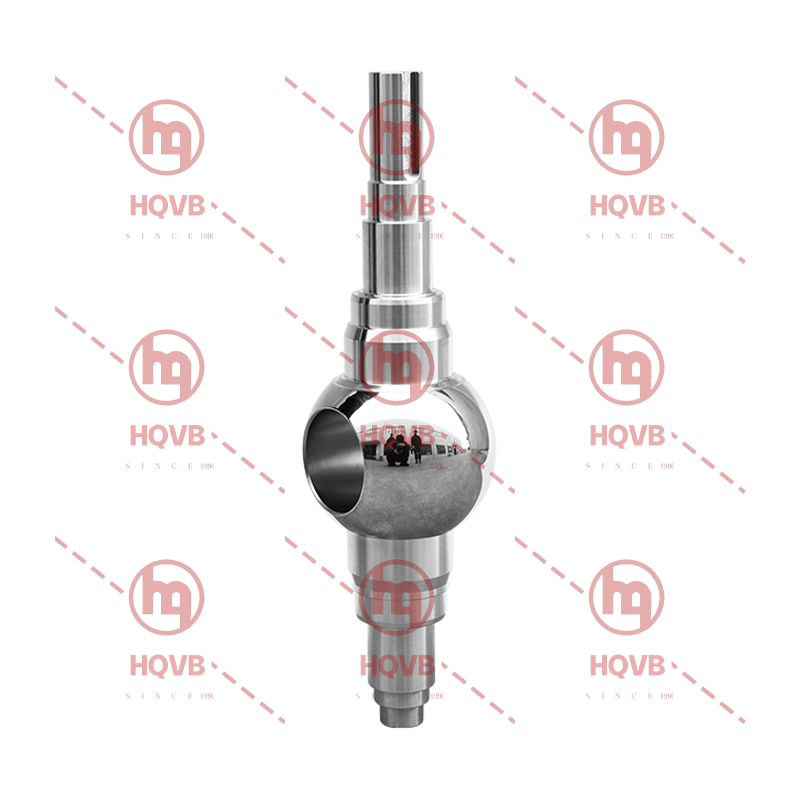

Ball valves are critical components in many industrial systems, controlling the flow of liquids and gases with high reliability. Precision ball valves, in particular, require exact tolerances and fine machining to ensure proper sealing and smooth operation. Similarly, high pressure brass ball valves are used in demanding environments where durability and resistance to pressure fluctuations are essential. The production of these components demands meticulous attention to detail and high manufacturing standards, making them well suited for automation improvements.

Automation in Machining and Fabrication

One of the primary areas where automation has made a significant impact is in machining processes. Computer Numerical Control (CNC) machines, integrated with automated systems, are now widely used to produce ball valve bodies, stems, and balls with consistent accuracy. The ability to program precise dimensions and repeat the process without human error reduces variability between batches and enhances product uniformity.

For precision ball valve components, where even minor deviations can affect performance, automated CNC machining helps maintain tight tolerances throughout the production cycle. Automated tool changers and robotic arms can operate continuously, allowing manufacturers to increase throughput without sacrificing quality.

In the case of high pressure brass ball valves, automated manufacturing lines can handle the complexity of working with brass alloys. Brass requires specific cutting tools and controlled machining parameters to avoid defects such as burrs or surface irregularities. Automation helps optimize these parameters and reduce waste, resulting in components that meet stringent pressure ratings.

Quality Control and Inspection

Automation also enhances quality control during and after production. Traditional inspection methods often involve manual measurement tools and human judgment, which can introduce inconsistencies. Automated inspection systems, including vision systems and laser scanners, can measure critical dimensions on precision ball valve parts quickly and accurately.

By integrating real-time monitoring with production, manufacturers can detect defects early and make immediate adjustments. This proactive approach reduces the risk of producing components that fail to meet specifications and helps maintain a steady flow of compliant products. For high pressure brass ball valve components, where leaks or failures can have serious consequences, automated testing and inspection ensure that each part performs as required.

Material Handling and Assembly

Automation extends beyond machining and inspection into material handling and assembly processes. Robotic arms and conveyors can transport raw materials and finished parts between stations, less manual labor and the risk of damage or contamination. This is particularly beneficial in clean manufacturing environments where maintaining component integrity is critical.

Assembly lines equipped with automated screwdrivers, presses, and torque tools can assemble ball valve components with repeatable precision. For complex valve designs involving multiple parts, automation helps maintain consistency in assembly and reduces the likelihood of human error, which can advance to leaks or operational issues.

Benefits of Automation for Ball Valve Production

The integration of automation in ball valve component manufacturing brings multiple benefits. It increases production efficiency by enabling continuous operation with less downtime. Automated systems can work through night shifts or extended hours, meeting the demand for precision ball valves and high pressure brass ball valves without interruption.

Second, automation enhances product quality through consistent manufacturing and precise control over critical parameters. This consistency is essential for components that must withstand harsh operating conditions and meet strict regulatory standards.

Third, automation improves workplace safety by reducing the need for manual handling of heavy or hazardous materials. Workers can focus on overseeing processes and maintaining equipment rather than performing repetitive or strenuous tasks.

Finally, automation enables manufacturers to be more flexible and responsive to market changes. Production lines can be quickly reprogrammed to accommodate design modifications or new product introductions, supporting a dynamic business environment.

Challenges and Considerations

While automation offers clear advantages, implementing automated systems requires careful planning and investment. The initial cost of equipment and software can be significant, and training staff to operate and maintain automated machinery is necessary. Additionally, integrating automation with existing processes may present technical challenges that require expertise and customization.

Manufacturers must also consider the balance between automation and skilled human input. While automation handles repetitive and precise tasks effectively, human oversight remains critical for troubleshooting, quality assurance, and innovation.

Automation is steadily transforming the production of ball valve components, particularly precision ball valves and high pressure brass ball valves. By enhancing machining accuracy, quality control, material handling, and assembly, automation enables manufacturers to produce reliable components that meet industrial requirements. As technology continues to evolve, further advancements in automation are expected to shape the future of ball valve manufacturing, supporting improved performance and efficiency across diverse applications.