Selecting the appropriate ball valve components is a critical step in ensuring the success and reliability of your piping or fluid control system. With numerous options available on the market, understanding the key features and applications of various ball valve types can help you make an informed decision that suits your specific project needs. This article provides a practical guide on how to choose the right ball valve components, focusing on the popular ball valve 2pc body, 3 port ball valve, and ductile iron ball valve options.

Understanding Ball Valve Components

Ball valves control the flow of liquids or gases by using a spherical disc, commonly referred to as the “ball,” which rotates within the valve body. When the ball’s hole aligns with the flow direction, the valve is open, allowing fluid to pass. When rotated 90 degrees, the hole is perpendicular to the flow path, effectively stopping flow.

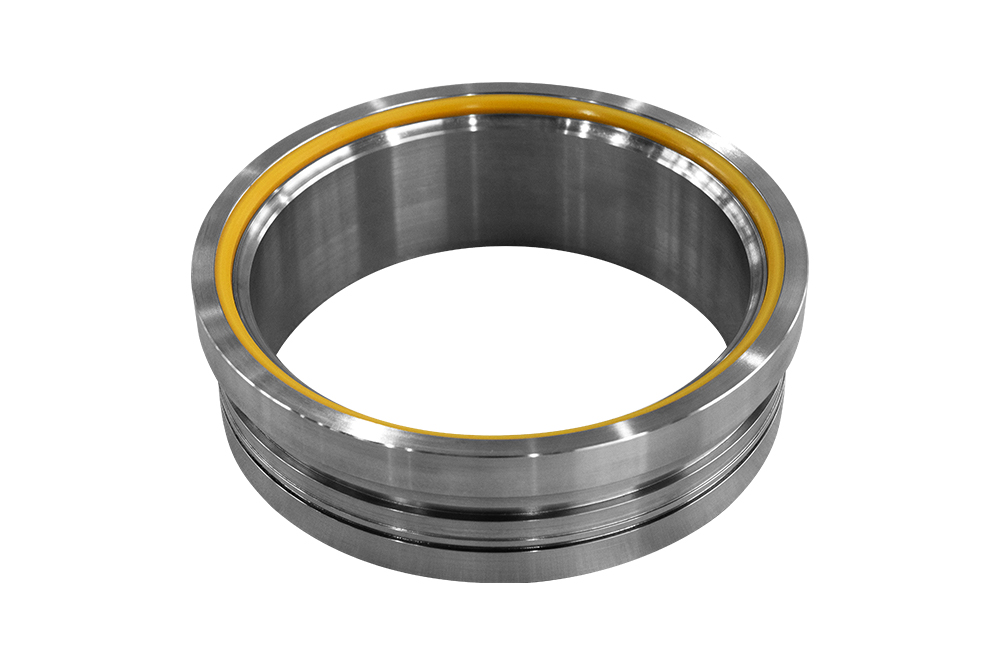

The valve’s body, stem, seats, seals, and handle are all crucial components. Selecting the right material and configuration for these parts can influence the valve’s durability, pressure handling, temperature tolerance, and suitability for specific media.

Ball Valve 2pc Body: Simplicity and Maintenance

The ball valve 2pc body design consists of two main body parts joined together, typically secured by bolts or threaded connections. This construction provides a balance between ease of maintenance and cost-efficiency.

Advantages:

The two-piece body design allows for straightforward disassembly, which can be beneficial for cleaning, inspection, or seat replacement without removing the entire valve from the pipeline. This feature is useful in applications where routine maintenance is expected or where downtime needs to be lessd.

Considerations:

While the 2pc body valve offers convenience, it may have slightly lower pressure ratings compared to multi-piece designs due to the body joint. It is important to check the pressure and temperature specifications relevant to your project to ensure compatibility.

3 Port Ball Valve: Versatility in Flow Control

The 3 port ball valve is distinguished by its three openings, allowing fluid to flow through multiple directions or to be diverted between two outlets. This type of valve provides versatile control options, making it suitable for complex piping systems.

Common Configurations:

3 port ball valves usually come in “L” or “T” port designs. The L-port allows switching flow between two different outputs, while the T-port can enable flow to or from multiple ports simultaneously, offering greater flexibility.

Applications:

The 3 port ball valve is widely used in applications where fluid diversion or mixing is required, such as in chemical processing, HVAC systems, and water treatment plants. It helps reduce the number of valves needed in a system, simplifying installation and control.

Material and Size Selection:

When selecting a 3 port ball valve, consider the material of the valve body and ball, along with the type of sealing seats to match the chemical compatibility and temperature requirements of your project.

Ductile Iron Ball Valve: Strength and Durability

The ductile iron ball valve is valued for its robust mechanical properties and resistance to impact and pressure. Ductile iron, a type of cast iron known for its enhanced ductility and toughness, is commonly used in valve bodies for industrial and municipal applications.

Advantages:

Compared to standard cast iron, ductile iron offers greater strength and resistance to cracking, making it suitable for higher pressure systems and environments where mechanical stress is a concern. It also provides good corrosion resistance when properly coated.

Typical Uses:

Ductile iron ball valves are often installed in water distribution, wastewater treatment, and general industrial fluid handling systems. They can handle moderate to high pressures and are effective in applications where durability is essential.

Coatings and Linings:

Many ductile iron valves are coated internally and externally with protective layers such as epoxy or polyurethane to enhance corrosion resistance, especially in wet or corrosive environments.

Key Factors When Choosing Ball Valve Components

Media Compatibility:

The valve materials must be compatible with the fluids or gases in your system. For example, ductile iron may not be suitable for highly acidic or corrosive chemicals without special linings.

Pressure and Temperature Ratings:

Always confirm that the valve components can handle the up to pressure and temperature conditions expected in your operation. The 2pc body valves may have limitations compared to other designs.

Valve Size and Connection Type:

Ensure the valve size matches your pipeline diameter. Connection methods such as threaded, flanged, or welded ends should align with your installation preferences and standards.

Maintenance Requirements:

Consider how often the valve will need inspection or servicing. The 2pc body valve design can facilitate easier maintenance compared to more complex assemblies.

Flow Control Needs:

Determine whether a simple on/off valve suffices or if you require a valve with multiple ports like the 3 port ball valve, for diversion or mixing tasks.

Choosing the right ball valve components depends on balancing the specific requirements of your project with the available valve designs and materials. The ball valve 2pc body offers a practical solution for applications where maintenance access is important. The 3 port ball valve adds versatility for complex flow control scenarios. Meanwhile, the ductile iron ball valve provides a durable option for systems needing enhanced mechanical strength.

Evaluating your project’s fluid characteristics, operating conditions, and maintenance plans will guide you to a suitable valve configuration, helping ensure reliable operation and longevity of your system.