As industrial environments evolve, the demand for resilient components has led to significant developments in the field of flow control. Among the components seeing renewed attention are the Hard Seal Ball and the seal ball valve, both of which are central to the functionality of various high-pressure and high-temperature systems. Industries such as petrochemical, power generation, and mining increasingly require equipment that can withstand challenging conditions while maintaining reliable performance.

The Hard Seal Ball is primarily recognized for its robust resistance to wear, corrosion, and thermal stress. Unlike soft-seated alternatives, it can maintain its structure and effectiveness even in harsh fluid systems. Engineers are focusing more attention on the surface treatment and material composition of these components. Alloy coatings, precise machining, and advanced heat treatment techniques contribute to enhancing the performance of the Hard Seal Ball without compromising on efficiency or durability.

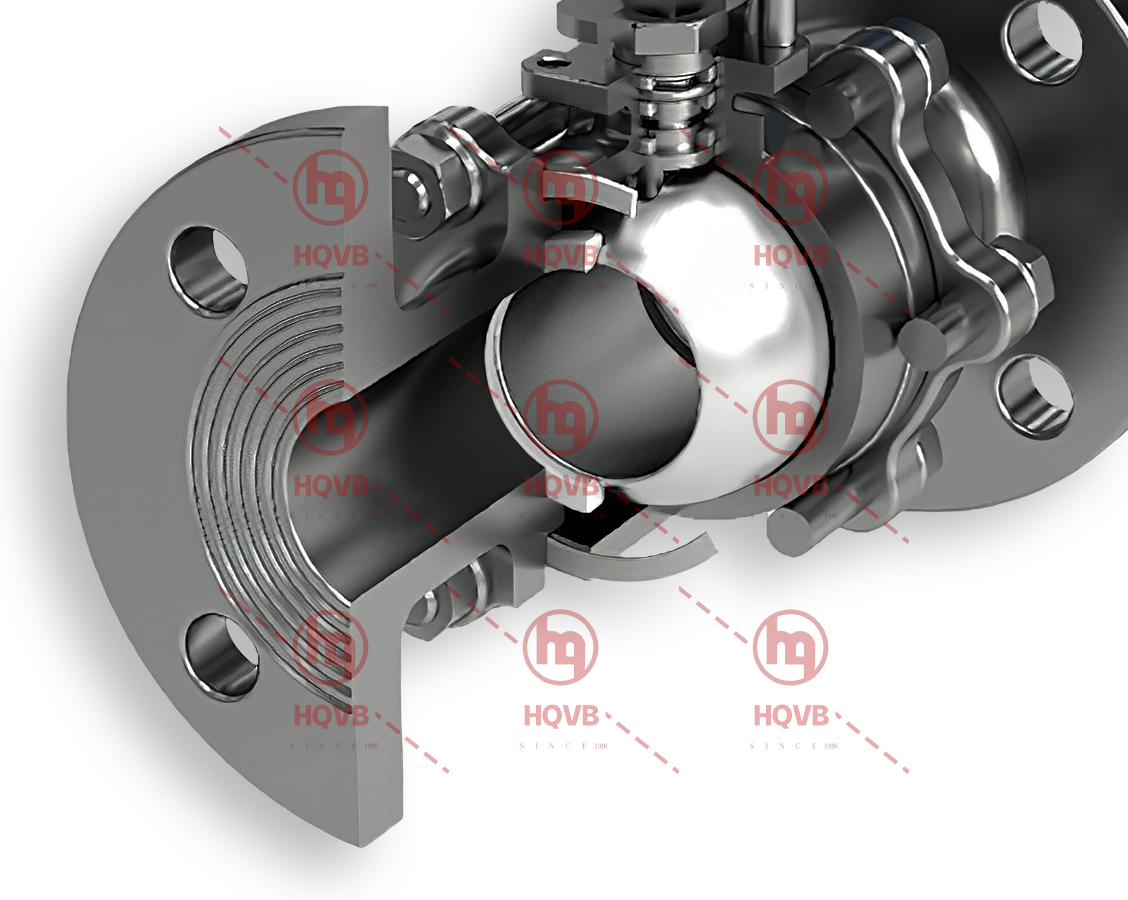

The seal ball valve plays an integral role in controlling the flow of liquids and gases in complex systems. Known for their tight shut-off capabilities, these valves are often used in processes where leakage is unacceptable. With growing awareness of sustainability and resource conservation, there is a push toward improving sealing performance while reducing maintenance frequency. In this context, the compatibility between the seal ball valve and the Hard Seal Ball has become a subject of close study and refinement.

Modern installations now place a premium on longer service life and reduced downtime. This shift has influenced how manufacturers design and test both the Hard Seal Ball and the seal ball valve. Simulated operational environments are increasingly used in product development to predict material behavior and failure points. As a result, products that enter the market are often more aligned with actual usage demands rather than theoretical models.

One of the notable shifts in this segment is the adoption of modular valve assemblies. With a modular approach, technicians can replace or upgrade the Hard Seal Ball independently, extending the lifespan of the seal ball valve without having to replace the entire unit. This feature brings added flexibility to facility maintenance operations and allows for a more tailored response to system-specific requirements.

Another area seeing advancement is in the integration of automation. Many seal ball valve systems now feature position sensors and remote actuation capabilities, which are especially beneficial in large-scale operations where manual intervention is either difficult or hazardous. As the Hard Seal Ball continues to be refined, its compatibility with automated systems is also receiving attention, ensuring that actuation forces remain within functional limits.

Across various regions, the engineering community is engaging in collaborative research to better understand material fatigue, particularly in relation to the Hard Seal Ball under fluctuating pressures and chemical exposures. These studies inform future design protocols, helping manufacturers develop valves that align better with international safety and performance standards.

The industrial landscape is driving tangible innovation in the realm of flow control components. Both the Hard Seal Ball and the seal ball valve are central to these improvements, offering solutions that meet the practical needs of evolving applications. As industries continue to push the boundaries of performance and reliability, it is likely that further enhancements in design, testing, and integration will continue shaping the future of these essential mechanical components.