Understanding Ball Valve 3 Pcs Body Design

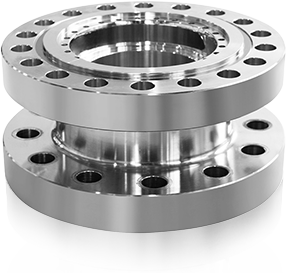

The ball valve 3 pcs body design is widely adopted across various industries due to its modular construction and ease of maintenance. This design consists of three separate pieces — the two end caps and the central body — bolted together to form a complete valve assembly. One of the advantages of this design is that it allows for easier servicing and replacement of internal components, such as the ball, stem, and seats, without removing the entire valve from the pipeline.

This feature makes the ball valve 3 pcs body particularly suitable for applications requiring frequent maintenance or part replacement. When combined with reinforced PTFE seats, this design enhances the valve’s ability to maintain tight sealing under varying pressure and temperature conditions, contributing to improved component reliability.

The Role of Reinforced PTFE Seats in Valve Performance

PTFE (polytetrafluoroethylene) has long been used as a seat material due to its chemical resistance, low friction, and temperature tolerance. However, standard PTFE seats may experience deformation or wear under high pressure or abrasive conditions, pilot to leaks and reduced valve lifespan.

Reinforced PTFE seats incorporate fillers such as glass fibers or carbon to increase mechanical strength and reduce cold flow, addressing some of the limitations of pure PTFE. This reinforcement improves wear resistance and dimensional stability, ensuring the seat maintains its sealing properties even after prolonged use.

The benefits of reinforced PTFE seats become especially significant in commercial ball valve applications, where valves must perform reliably under frequent operation cycles and in diverse environmental conditions. The enhanced durability reduces maintenance frequency and the risk of unexpected downtime, contributing to smoother operational workflows.

Application of Reinforced PTFE Seats in a 3 Inch Stainless Steel Ball Valve

A 3 inch stainless steel ball valve equipped with reinforced PTFE seats is commonly used in commercial and industrial settings, such as water treatment, chemical processing, and HVAC systems. Stainless steel offers corrosion resistance and strength, suitable for demanding environments, while the reinforced PTFE seats ensure the valve’s internal sealing components perform consistently.

The combination of a stainless steel body and reinforced seats allows the valve to handle a wide range of fluids, including aggressive chemicals and abrasive slurries, without compromising sealing integrity. In addition, the reinforced PTFE seats accommodate thermal expansion and contraction better than standard materials, reducing the likelihood of leakage over time.

Because a 3 inch stainless steel ball valve is a mid-sized valve, it offers a balance between flow capacity and installation space, making it a practical choice for many commercial systems requiring dependable shut-off capabilities.

Commercial Ball Valve Use and Maintenance

Commercial ball valves often encounter frequent operation and a variety of pressures and temperatures, requiring components designed to withstand such conditions. Incorporating reinforced PTFE seats in these valves offers advantages in reducing wear and sealing failures.

Maintenance procedures benefit from the ball valve 3 pcs body design by allowing technicians to replace worn seats without dismantling the entire pipeline system. This reduces downtime and maintenance costs, which are significant considerations in commercial applications where process continuity is essential.

Routine inspections of seat condition and valve operation help detect early signs of wear or leakage. Reinforced PTFE seats typically extend intervals between maintenance, but regular checks ensure operational reliability over the valve’s service life.

Environmental and Operational Advantages

In addition to mechanical reliability, reinforced PTFE seats contribute to environmental safety by less leakage risks, which can be particularly critical when valves handle hazardous or environmentally sensitive fluids. The robust sealing performance reduces the chance of accidental releases, supporting compliance with environmental regulations.

Operationally, valves fitted with reinforced PTFE seats often demonstrate smoother operation due to reduced friction between the ball and seats. This characteristic lowers the torque needed to operate the valve, which can extend the actuator and manual handle lifespans.

The integration of reinforced PTFE seats in ball valve components represents a significant step in improving the reliability and durability of industrial and commercial valves. When combined with a ball valve 3 pcs body design, these seats facilitate maintenance and enhance operational consistency. The application of reinforced PTFE seats in a 3 inch stainless steel ball valve is a practical solution for systems requiring robust sealing, chemical resistance, and reliable performance.

For commercial ball valve users, these advancements translate into reduced maintenance needs, longer service life, and safer operation. The reinforced seat material supports performance under challenging conditions while maintaining the sealing integrity essential to valve function.

As fluid control systems continue to evolve, reinforced PTFE seats remain a valuable component in achieving dependable valve performance without reliance on bad or superlative claims, focusing instead on tangible improvements in component reliability.