The Importance of Fatigue Testing for Valve Components

Fatigue testing is a critical procedure designed to evaluate how valve components perform under repeated stress and cyclic loading. Unlike a one-time pressure or leak test, fatigue testing simulates long-term operational conditions that valves experience during service. This type of testing helps identify potential weaknesses or points of failure that may develop over time, ensuring that safety-critical components remain reliable throughout their lifespan.

Valves, particularly in applications involving hazardous fluids or bad conditions, must withstand numerous cycles of opening and closing without degradation in performance. Fatigue testing allows manufacturers to understand how components such as metal seated ball valves behave when exposed to these conditions repeatedly, which is essential for applications where valve failure could advance to safety risks or costly downtime.

Metal Seated Ball Valves for High Temperature Applications

Metal seated ball valves are often chosen for high temperature applications due to their robust design and resistance to wear. The metal seats provide durability where traditional soft seats might fail under bad heat or abrasive conditions. Fatigue testing for these valves focuses not only on the ball and stem but also on the integrity of the metal seat, which is subjected to high pressures and thermal expansion cycles.

During fatigue testing, metal seated ball valves are cycled through numerous open-close operations at elevated temperatures to replicate real-world conditions. This process helps to reveal how the metal seat maintains its sealing ability and structural integrity despite thermal stresses. The results from these tests inform design improvements, ensuring that the valves can operate safely within their specified temperature ranges.

Characteristics of Stainless Steel Floating Ball Valves

Stainless steel floating ball valves are another category that requires extensive fatigue testing due to their widespread use in corrosive and industrial environments. These valves feature a ball that “floats” between two seats, allowing it to move slightly and create a tight seal when closed. The floating design can adapt to minor misalignments and pressure fluctuations, but it also means the ball and seats experience dynamic forces during operation.

Fatigue testing of stainless steel floating ball valves involves subjecting the valve to continuous cycles of pressure and mechanical stress. This helps verify that the floating ball and its seats can withstand repeated operation without developing leaks or material fatigue. The corrosion resistance of stainless steel combined with successful fatigue test results provides confidence in the valve’s performance in chemical processing, food and beverage, and pharmaceutical applications.

Performance of 1 Inch Flanged Ball Valves Under Stress

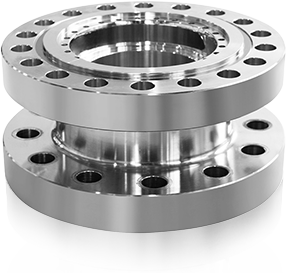

The 1 inch flanged ball valve is a common size used in many industrial piping systems where flange connections are preferred for their ease of installation and maintenance. Despite its relatively small size, the 1 inch flanged ball valve must meet strict performance standards, especially when deployed in safety-critical systems.

Fatigue testing for these valves focuses on the sealing surfaces, stem, flange connections, and overall valve body. The tests simulate operational cycles under various pressure and temperature conditions to detect any signs of material fatigue, leakage, or mechanical failure. Since flanged connections involve bolts and gaskets, the testing also evaluates the flange joint’s ability to maintain integrity during repeated thermal expansion and contraction.

By analyzing the fatigue test data, manufacturers can adjust the design parameters or materials used in 1 inch flanged ball valves to improve durability and safety without compromising functionality.

Integrating Fatigue Testing Into Quality Control

Fatigue testing is integrated into the overall quality control and product development process for valve components. It provides essential feedback that complements other tests such as pressure testing, leak testing, and material certification. Components that successfully pass fatigue tests are considered suitable for use in critical systems, including oil and gas pipelines, power plants, chemical processing, and other industries where valve reliability is essential.

This type of testing also supports compliance with international standards and regulatory requirements that demand proof of durability and safety. Customers and end-users gain confidence knowing that valves undergo comprehensive fatigue assessments before shipment.

Valve components such as metal seated ball valves designed for high temperature, stainless steel floating ball valves, and 1 inch flanged ball valves are essential elements in industrial systems that require dependable flow control. Fatigue testing ensures these components can handle the stresses and cycles typical in real-world applications, particularly in safety-critical environments. By continuously evaluating and improving valve designs through fatigue testing, manufacturers contribute to safer operations and longer service lives for their products.