Valve components used in this sector must withstand harsh conditions such as high pressures, low temperatures, and exposure to corrosive substances. Among the various valve types, the cast iron flanged ball valve has become a common choice due to its robustness and ease of maintenance. Additionally, innovations like quiet ball valves and advanced ball valve seat inserts contribute to improved performance and longevity in demanding petrochemical applications.

Cast Iron Flanged Ball Valve in Petrochemical Settings

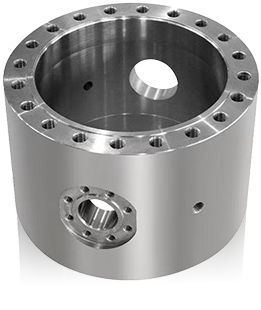

Cast iron flanged ball valves are widely used in petrochemical facilities for controlling the flow of liquids and gases. The cast iron material offers good mechanical strength and corrosion resistance, making it suitable for moderate pressure and temperature environments commonly found in petrochemical processes. The flanged design provides secure, leak-proof connections between pipes, allowing for easier installation and removal during maintenance or system upgrades.

These valves offer a straightforward quarter-turn operation, which simplifies the control of flow. The ball inside the valve, which rotates to open or close the passage, is precisely machined to ensure smooth operation and effective sealing. Because petrochemical applications often involve handling aggressive fluids, the durability of the cast iron body and the integrity of the sealing surfaces are essential to prevent leaks that could advance to safety hazards or costly downtime.

The Role of Quiet Ball Valves

Noise reduction is another important consideration in petrochemical plants, where valve operation can generate high levels of sound due to fluid turbulence and pressure drops. Quiet ball valves have been developed to address this challenge by incorporating design elements that less vibration and noise during flow control. These valves typically feature enhanced internal flow paths and improved sealing technology to reduce the turbulence that causes noise.

The implementation of quiet ball valves helps create a safer working environment by lowering sound levels, which can otherwise contribute to hearing damage or increased stress among plant personnel. Furthermore, quieter valve operation may also reduce mechanical wear, extending the service life of the components and reducing maintenance costs.

Importance of Ball Valve Seat Inserts

A critical element in the functionality of ball valves is the ball valve seat insert. This component provides the sealing interface between the rotating ball and the valve body, ensuring that fluid does not leak when the valve is closed. In petrochemical applications, the seat insert must be resistant to chemical attack, thermal degradation, and mechanical wear.

Materials commonly used for ball valve seat inserts include PTFE (polytetrafluoroethylene), reinforced PTFE, and other engineered plastics that offer good chemical resistance and low friction. The choice of seat insert material depends on the specific fluid characteristics and operating conditions. For example, reinforced PTFE inserts may be selected for applications where higher temperatures or abrasive media are present.

The design of the seat insert also plays a role in maintaining a tight seal under varying pressures. Some inserts are engineered with spring-loaded features or elastomeric components to compensate for wear and thermal expansion, helping to maintain sealing integrity over time.

Integration of Components for Reliable Performance

In petrochemical plants, valve assemblies often combine several components, such as cast iron flanged ball valves, quiet ball valves, and carefully selected ball valve seat inserts to meet the specific needs of each process line. Engineers must consider factors such as pressure rating, temperature range, chemical compatibility, and noise levels when selecting these components.

Maintenance practices also influence the performance and lifespan of valve components. Regular inspection of seat inserts for wear or damage, lubrication of moving parts, and testing for leaks are part of standard protocols to ensure continued reliable operation. The modular design of many ball valves allows for easy replacement of seat inserts or other internal components without removing the entire valve from the pipeline, reducing downtime and labor costs.

Valve components designed for petrochemical applications must balance durability, safety, and operational efficiency. The cast iron flanged ball valve provides a sturdy and maintainable option for many flow control needs. Quiet ball valves contribute to safer and more comfortable plant environments by reducing noise generated during operation. Meanwhile, the ball valve seat insert plays a vital role in maintaining leak-free sealing under challenging chemical and temperature conditions.

By carefully selecting and integrating these components, petrochemical facilities can ensure reliable flow control and support safe, continuous operation in demanding industrial environments.