When it comes to optimizing valve performance and ensuring reliable sealing, the choice of valve ball plays a crucial role. A Hard Seal Ball offers exceptional durability and sealing ability, making it an ideal choice for high-pressure and high-temperature applications. Combined with a Custom Ball Valve Ball, this combination provides a highly tailored solution to meet specific operational requirements in various industries, from oil and gas to water treatment. In this article, we will explore the advantages of using Hard Seal Balls in custom ball valves and why they are an excellent choice for performance-driven applications.

A Hard Seal Ball is designed to provide superior sealing performance, particularly in systems that require high reliability under harsh conditions. The key benefit of a Hard Seal Ball is its ability to withstand extreme pressure and temperature fluctuations without compromising its sealing capabilities. This makes it ideal for industrial applications, where safety and efficiency are paramount.

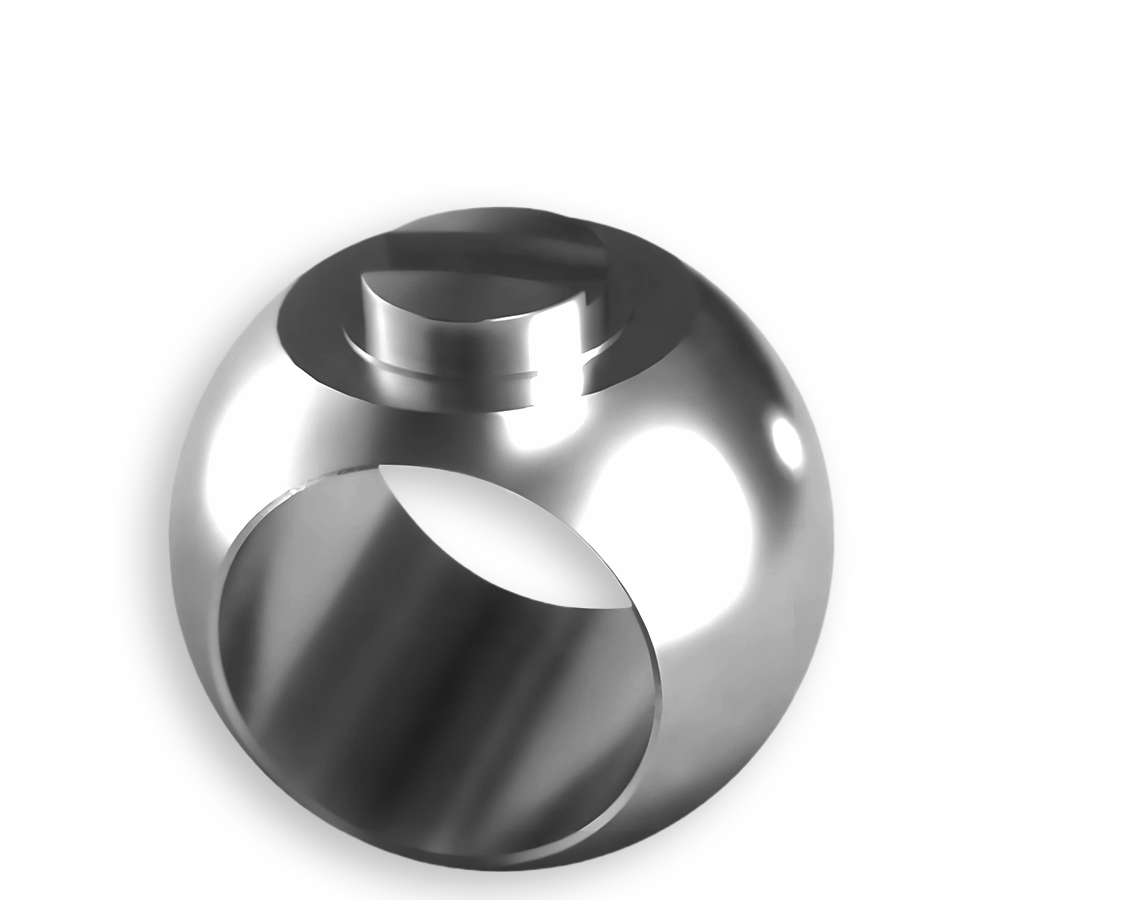

In a typical valve system, the ball is responsible for controlling the flow of liquids or gases. A Hard Seal Ball ensures that the ball and seat remain tightly sealed, reducing the chances of leakage, and increasing the system’s longevity. By using high-quality materials such as stainless steel or ceramic, the Hard Seal Ball is resistant to wear, corrosion, and abrasion, providing a long-lasting solution for demanding environments.

While Hard Seal Balls are an excellent choice for ensuring performance, the need for Custom Ball Valve Balls has been growing in industries where specific requirements dictate the need for tailored solutions. A Custom Ball Valve Ball can be designed to meet unique operational needs, such as specific sizes, materials, and flow control characteristics.

Customization allows for flexibility, ensuring that the valve ball fits perfectly within the system, providing optimal performance in a way that off-the-shelf products cannot. For example, a Custom Ball Valve Ball can be manufactured to meet the exact pressure, temperature, and flow requirements of an application. By tailoring the ball valve’s design, manufacturers can create a solution that maximizes efficiency, reduces maintenance, and minimizes operational risks.

The combination of a Hard Seal Ball and a Custom Ball Valve Ball offers unmatched performance and efficiency. By customizing the ball valve to the specific needs of an application, industries can optimize flow rates, control pressures, and reduce the likelihood of valve failure.

Whether in the oil and gas industry, water treatment facilities, or manufacturing plants, the use of a Custom Ball Valve Ball allows for greater control and precision. Moreover, the Hard Seal Ball ensures that once the valve is closed, it remains sealed, preventing leaks and minimizing downtime. This reliability is crucial in industries where the cost of system failure can be significant.

The durability of both Hard Seal Balls and Custom Ball Valve Balls is key to minimizing maintenance costs and downtime. Hard seals are engineered to resist wear and tear over time, extending the life of the valve and reducing the need for frequent replacements. Furthermore, Custom Ball Valve Balls can be designed to suit the specific materials in use within the system, preventing unnecessary damage from chemical or abrasive interactions.

Regular maintenance checks are still important, but using a Hard Seal Ball and Custom Ball Valve Ball reduces the likelihood of unexpected failures, saving companies both time and money in the long run.

Choosing the right ball valve ball is critical for ensuring optimal performance in various industries. The Hard Seal Ball offers superior sealing capabilities, ensuring high-pressure systems remain leak-free and efficient. When combined with a Custom Ball Valve Ball, you get a fully tailored solution that can meet specific operational requirements, offering greater flexibility, durability, and cost savings.

Whether you are looking to replace an existing valve or build a completely customized system, using a Hard Seal Ball and Custom Ball Valve Ball is an investment in long-term performance and reliability. With the right design and materials, these components can deliver the ultimate in valve performance for your industrial applications.

When it comes to designing reliable and high-performance valve systems, selecting the right components is crucial. Among the key components, the Hard Seal Ball and Custom Ball Valve Ball play vital roles in ensuring long-term durability, efficient flow control, and secure sealing. In industries like oil and gas, chemical processing, and water treatment, the need for high-quality valve components is paramount to maintaining safety, efficiency, and performance. This article explores the benefits of Hard Seal Balls and Custom Ball Valve Balls, highlighting why these components are critical for demanding applications.