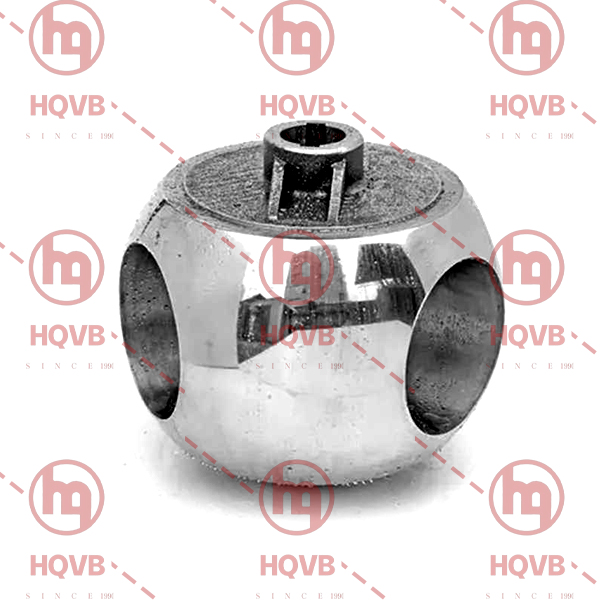

In today’s rapidly evolving industrial landscape, performance expectations for fluid control systems are being redefined. Engineers, distributors, and project owners across overseas markets are discussing how internal valve components influence reliability and operational confidence. Among the most frequently mentioned elements are the Hard Seal Ball, which directly affects sealing stability, and the Ball Valve Stem, a component increasingly recognized for its role in precise control and long-term durability.

This shift in attention reflects a broader change in how industrial buyers evaluate valve solutions.

In the past, many buyers focused primarily on the overall valve assembly. However, global sourcing discussions now reveal a deeper evaluation process. Procurement teams are examining how individual components contribute to system performance over time.

This trend has elevated the importance of internal structures, encouraging buyers to understand how sealing mechanisms and control transmission elements function under real operating conditions.

Hard seal designs are gaining attention due to their perceived ability to support stable operation in complex environments. Overseas professionals often associate these designs with improved resistance to wear and consistent sealing behavior.

As applications grow more diverse, buyers seek components that help maintain performance consistency without frequent adjustments. This has positioned hard seal balls as a key talking point in international engineering communities.

While sealing components ensure closure, valve stems determine how effectively that closure is achieved. Smooth operation, predictable torque response, and alignment accuracy are increasingly valued in global markets.

Ball valve stems manufactured with attention to dimensional consistency help reduce operational friction and improve control responsiveness. These qualities are frequently mentioned in discussions about user safety and system efficiency.

Across overseas social media platforms and industry forums, buyers consistently emphasize the importance of manufacturing credibility. They want assurance that valve components are produced under stable processes with clear quality standards.

Suppliers that demonstrate strong control over machining, surface treatment, and inspection are more likely to earn trust. This confidence extends beyond individual orders and supports long-term cooperation.

Maintenance efficiency is another recurring theme in global buyer conversations. Components that support smoother operation and predictable wear patterns are often preferred.

Hard seal balls designed for structural stability can help reduce concerns related to leakage or performance drift. Similarly, robust valve stem construction contributes to easier servicing and fewer operational interruptions.

Industrial buyers increasingly look for components that can be applied across multiple sectors. Versatility allows procurement teams to simplify inventory management and respond to changing project requirements.

Valve internals that support different working conditions without extensive redesign are particularly attractive. This adaptability enhances the overall value proposition of precision-engineered components.

Sustainability is no longer limited to material sourcing alone. Global buyers are also considering how component longevity affects environmental impact.

Durable sealing and control components help extend service life and reduce replacement frequency. This aligns with international efforts to promote more responsible industrial operations while maintaining performance standards.

As projects vary by region and application, customization has become an important consideration. Buyers appreciate manufacturers who can tailor component specifications to meet specific system needs.

Flexible design options for hard seal balls and ball valve stems allow customers to achieve better compatibility without compromising reliability, making customization a strong differentiator in global markets.

Clear technical communication is essential when working with international clients. Buyers value suppliers who can explain design intent, application suitability, and production capabilities with transparency.

This openness helps reduce uncertainty during procurement and reinforces trust throughout the cooperation process.

As global industries continue to demand higher reliability and efficiency, attention is increasingly focused on the internal elements that determine valve performance. Buyers are recognizing that dependable operation begins with well-engineered components.

By prioritizing advanced Hard Seal Ball designs and precision-crafted Ball Valve Stem solutions, manufacturers can better support modern industrial systems and meet the evolving expectations of international markets.