As industrial systems become more specialized and interconnected, global buyers are rethinking how they evaluate valve reliability. Instead of focusing solely on external specifications, decision-makers are looking deeper into internal construction. In this shift, the Hard Seal Ball is increasingly discussed for its sealing role, while the Ball Valve Stem is gaining recognition as a critical factor in operational accuracy and service stability.

This growing awareness reflects a more mature and informed global market.

Across overseas engineering forums and professional networks, conversations are moving beyond brand names and general product descriptions. Buyers want to understand how valves perform after extended use, especially in applications where stability and control consistency matter.

This has led to a greater appreciation of how internal components interact under pressure, temperature variation, and repeated operation.

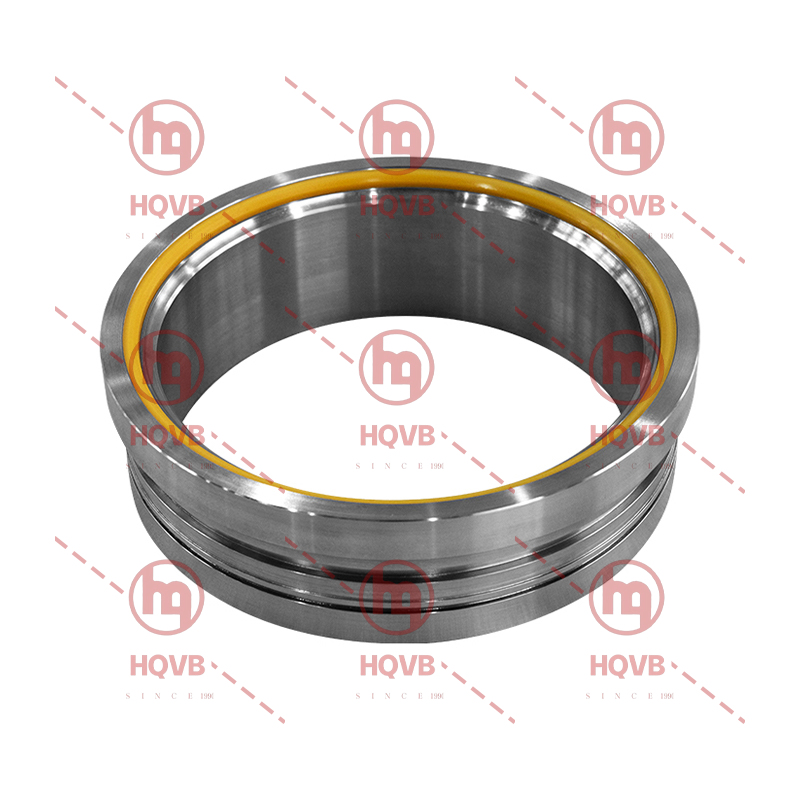

Sealing performance remains one of the most discussed topics among industrial users. Hard seal structures are often associated with dependable closure behavior and reduced performance fluctuation.

When a valve maintains stable sealing characteristics, it supports smoother system operation and helps users feel confident in long-term deployment. This perception has made hard seal balls a frequent consideration during technical evaluations.

While sealing ensures closure, precise control depends on how force is transmitted. Valve stems play a key role in converting user input into mechanical movement.

International buyers increasingly value stems that offer smooth rotation, predictable feedback, and consistent alignment. These qualities contribute to safer operation and improved user experience, especially in applications requiring frequent adjustments.

Manufacturing discussions on overseas platforms show a clear preference for suppliers with stable production capabilities. Buyers want assurance that every component meets the same quality expectations, not just a single sample.

Consistent machining, controlled material selection, and standardized inspection processes all influence purchasing decisions. This focus on production reliability highlights the importance of experienced component manufacturers.

Maintenance efficiency has become a major concern across industries. Components designed with long-term usability in mind help reduce downtime and simplify service procedures.

Hard seal balls with reliable surface integrity can contribute to predictable wear patterns. Similarly, well-finished valve stems support smoother disassembly and reassembly, which appeals to maintenance teams worldwide.

Versatility is another topic frequently discussed by global buyers. Many projects require components that can be adapted to different systems without major redesign.

Valve internals that support a wide range of applications allow procurement teams to streamline sourcing and respond more flexibly to changing project demands. This adaptability is especially valuable in international supply chains.

Beyond design concepts, craftsmanship is gaining attention. Buyers often associate refined surface treatment and precise tolerances with better overall performance.

This emphasis on detail reflects a broader expectation: components should not only function properly but also demonstrate a level of manufacturing care that supports long-term reliability.

In international trade, communication is just as important as product quality. Buyers appreciate suppliers who clearly explain component characteristics, application scenarios, and customization possibilities.

Transparent communication helps reduce misunderstandings and builds trust, which is essential for sustainable global cooperation.

As industrial projects become more diverse, standardized solutions are not always sufficient. Buyers increasingly look for partners who can adjust specifications to meet specific requirements.

Customizable hard seal balls and valve stems allow users to optimize system compatibility without sacrificing performance, making customization a strategic advantage.

The global valve market is entering a stage where internal components receive the attention they deserve. Buyers now understand that reliability, control, and maintenance efficiency all depend on well-designed internals.

By focusing on precision-engineered Hard Seal Ball solutions and carefully manufactured Ball Valve Stem components, suppliers can better meet evolving international expectations and support the next generation of industrial systems.