The oil and gas industry relies heavily on reliable flow control systems to ensure safety, efficiency, and durability across its various operations. Among the critical components used in these systems, ball valves play a significant role due to their straightforward operation and ability to provide a tight shut-off. This article explores key aspects of ball valve components in oil and gas applications, with a particular focus on the gunmetal ball valve and the ball valve PTFE seat, which are widely employed to address the demanding conditions in this sector.

Role of Ball Valve Components in Oil and Gas

Ball valves are essential in controlling the flow of liquids and gases within pipelines and processing facilities. Their design allows quick quarter-turn operation, making them favorable for emergency shutoff and regular process control. The reliability of ball valves depends largely on the quality of their components, which must withstand high pressures, corrosive fluids, temperature variations, and mechanical wear.

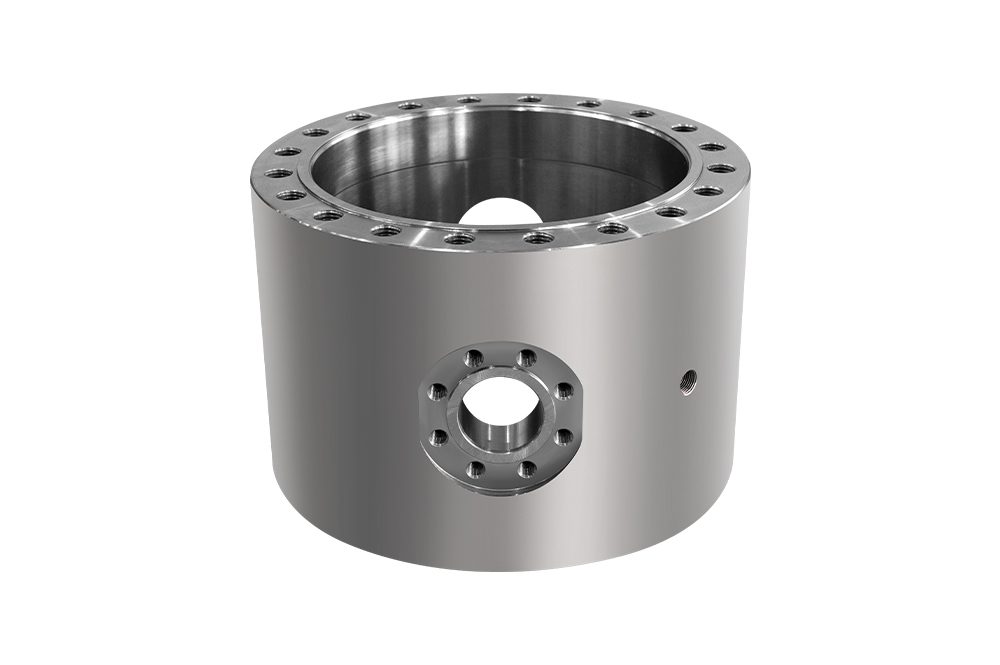

The oil and gas sector often presents challenging environments, including offshore rigs, refineries, and transportation pipelines, where materials and design must comply with rigorous standards. Components such as valve bodies, balls, stems, seats, and seals are engineered to maintain integrity and functionality under these harsh conditions.

Gunmetal Ball Valve: Material Advantages

One component material gaining continued interest in oil and gas applications is gunmetal, an alloy primarily composed of copper, tin, and zinc. The gunmetal ball valve offers several properties that make it suitable for specific environments within the industry.

Gunmetal’s inherent corrosion resistance, particularly against seawater and various chemicals, helps prolong valve life in marine and offshore installations. This corrosion resistance is critical because exposure to saline water and aggressive fluids is common in oil extraction and transport.

Additionally, gunmetal’s mechanical properties provide a good balance between strength and machinability, allowing precise manufacturing of valve components with tight tolerances. This precision contributes to consistent sealing performance and reduced leakage risk, which is vital in preventing hazardous emissions or fluid loss.

While gunmetal valves are not universally applied to all oil and gas operations, they are often selected for certain pipeline sections, control valves, and instrumentation connections where moderate pressure and corrosion resistance are prioritized.

Ball Valve PTFE Seat: Sealing Performance

The sealing mechanism within ball valves is crucial for controlling fluid passage and preventing leaks. One widely used material for valve seats is PTFE (Polytetrafluoroethylene), a synthetic fluoropolymer known for its chemical inertness and low friction.

The ball valve PTFE seat is designed to provide a tight seal between the valve ball and the body, ensuring reliable shutoff even under varying pressure and temperature conditions. PTFE seats are especially favored when handling corrosive or aggressive media because of their resistance to acids, bases, and solvents.

In oil and gas operations, the use of PTFE seats helps reduce maintenance requirements due to the material’s durability and self-lubricating properties. This also helps extend the service interval of valves in critical pipelines and processing units.

However, PTFE seats have temperature limitations and may deform under very high temperatures, typically above 260°C (500°F). Therefore, the selection of seat material must consider the specific operating temperature range alongside the chemical environment.

Challenges and Considerations

While components like gunmetal ball valves and PTFE seats provide advantages, there are several challenges associated with their use in oil and gas.

The compatibility of materials with the fluids handled is critical. Some hydrocarbons and additives can degrade PTFE over time, requiring careful selection or the use of alternative seat materials such as reinforced PTFE or other fluoropolymers.

Secondly, pressure ratings and mechanical strength must align with operational requirements. Gunmetal, while corrosion-resistant, may have pressure limitations compared to stainless steel or other alloys used in high-pressure systems. Consequently, understanding the application context helps determine when gunmetal ball valves are appropriate.

Thirdly, maintenance and inspection protocols must be tailored for the valve components in use. Regular monitoring for signs of wear, seat deformation, or corrosion can prevent failures that could advance to safety hazards or operational downtime.

Industry Trends and Future Directions

The oil and gas industry continues to explore new materials and designs to improve valve performance. Composite materials, enhanced coatings, and advanced polymers are under evaluation to address increasing demands for durability and safety.

For ball valve components, the integration of advanced sealing technologies and surface treatments may improve compatibility with harsh chemicals and extend service life. Meanwhile, digital monitoring systems are becoming more common, allowing real-time assessment of valve condition and predictive maintenance.

In the context of sustainability, materials that can be recycled or have a lower environmental footprint are gaining attention. Although gunmetal and PTFE have proven track records, research into alternatives that maintain performance while reducing environmental impact is ongoing.

Ball valve components such as the gunmetal ball valve and the ball valve PTFE seat serve important roles within the oil and gas sector, addressing specific requirements for corrosion resistance, sealing reliability, and mechanical integrity. Understanding the material properties, application constraints, and maintenance needs is essential for selecting the appropriate components that ensure safe and efficient flow control.

As the industry evolves, continued innovation in materials and technologies will influence how ball valve components are designed and deployed, supporting the complex and demanding operations of oil and gas production and transportation.