In recent years, the demand for smaller, more efficient mechanical components has driven significant innovation across many industries. Among these, the miniaturization of ball valve components has become a notable trend, especially for compact systems where space, weight, and performance must be balanced carefully. This article explores the ongoing developments in the miniaturization of ball valve components, with a focus on their application in compact systems and highlights the roles of stop ball valves and sus ball valves within this context.

The Need for Miniaturization in Compact Systems

Compact systems, such as medical devices, instrumentation, automotive assemblies, and various industrial applications, require components that deliver reliable performance in restricted spaces. Traditional ball valve assemblies, while effective, often occupy more space than newer compact designs can afford. The miniaturization of these valve components allows engineers to maintain or improve flow control functionality while reducing the size and weight of the entire system.

Smaller valve components can contribute to faster response times, reduced fluid volume requirements, and lower energy consumption. Additionally, compact ball valves improve integration flexibility, enabling their use in applications previously limited by spatial constraints.

Key Features of Miniaturized Ball Valve Components

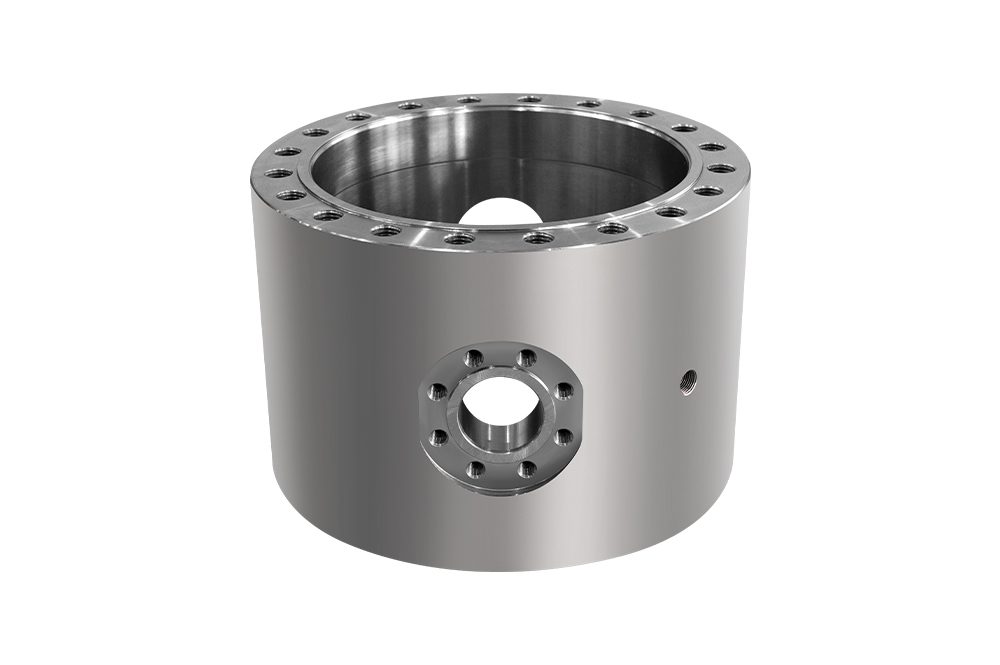

When discussing miniaturized ball valve components, certain technical features are essential to consider. These include precision machining, material selection, sealing technology, and overall component design. Miniaturized valves must maintain tight tolerances to ensure leak-free operation, even when operating under high pressure or temperature variations.

Materials like stainless steel, often referred to as sus ball valve components, are frequently employed due to their corrosion resistance, strength, and ability to withstand harsh environments. SUS (Steel Use Stainless) grades, such as SUS304 or SUS316, offer a reliable balance between durability and machinability, making them a popular choice for miniaturized ball valves used in compact systems.

Stop Ball Valve: Role and Adaptations in Miniaturization

A stop ball valve is a type of valve commonly used to control or completely shut off the flow within a piping system. Its simple design — typically featuring a spherical ball with a bore through the center — allows quick operation and reliable sealing. In miniaturized form, stop ball valves provide essential shutoff functionality for compact devices, enabling precise control without requiring extensive space.

Recent trends have seen stop ball valves manufactured with enhanced surface finishes and tighter tolerances, allowing for smoother rotation and reduced wear. Miniaturized stop ball valves are often integrated with quick-connect fittings or threaded ends, facilitating easier installation in confined spaces. The reduction in size also necessitates innovations in actuator mechanisms, often relying on micro-motors or manual controls optimized for small-scale operation.

SUS Ball Valve: Material Considerations in Miniaturized Designs

The use of sus ball valve components plays a critical role in the successful miniaturization of ball valves. Stainless steel alloys provide the necessary mechanical properties while maintaining resistance to corrosion, an important factor in many compact system environments such as chemical processing, food and beverage, and pharmaceuticals.

Miniaturized sus ball valves benefit from advances in precision CNC machining, which enable the creation of smaller components without compromising strength or surface quality. Additionally, surface treatments such as electropolishing and passivation improve corrosion resistance and reduce friction, enhancing the valve’s lifespan in compact assemblies.

The challenge in miniaturized sus ball valves lies in balancing weight reduction with mechanical robustness. Thinner walls and smaller components must still withstand operational pressures, which requires careful design and testing.

Manufacturing Challenges and Solutions

Manufacturing miniaturized ball valve components presents several challenges. Achieving the necessary precision on a smaller scale demands advanced machining techniques and stringent quality control processes. Tolerances that might be acceptable on larger valves must be tightened as component sizes shrink to avoid leaks and mechanical failure.

Material handling becomes more delicate, and assembling tiny components requires specialized tools and fixtures. Automation and robotic assembly lines are increasingly employed to ensure consistency and repeatability in manufacturing miniaturized valves.

To maintain the functionality of stop ball valves and sus ball valves at reduced sizes, manufacturers often utilize advanced sealing materials and designs, including PTFE and elastomer seals engineered specifically for smaller bore diameters. These seals must maintain integrity under variable temperatures and pressures.

Applications Driving the Miniaturization Trend

Several industries are pushing the miniaturization trend for ball valve components. Medical devices require precise flow control in a small space, often integrated within complex diagnostic or therapeutic equipment. Compact instrumentation systems used in analytical laboratories benefit from smaller valves to improve fluid handling without enlarging the device footprint.

Automotive and aerospace sectors also demand miniaturized ball valves for fuel, cooling, and lubrication systems, where weight and space savings translate directly into improved performance and fuel efficiency.

In industrial automation, smaller ball valves facilitate the design of modular, space-saving machinery that can operate in tight environments, such as semiconductor fabrication or food processing plants.

The miniaturization of ball valve components represents a significant advancement for compact system design. By leveraging materials like sus ball valves and optimizing the design of stop ball valves, manufacturers can provide smaller, reliable, and efficient valve solutions suited for a wide range of applications. Ongoing innovations in machining technology, sealing materials, and assembly processes continue to push the boundaries of what is achievable in compact ball valve designs, opening new possibilities for system integration and performance.