In the field of fluid control, ball valves play a critical role in managing flow with reliability and precision. The ongoing development of ball valve accessories has contributed significantly to expanding the capabilities and flexibility of these systems. As industries increasingly demand adaptable and efficient solutions, the enhancements in ball valve accessories offer practical benefits that address evolving operational needs.

Ball valve accessories encompass a variety of add-ons designed to improve installation, operation, and maintenance. These include items such as actuators, positioners, limit switches, and mounting kits. The integration of these accessories allows users to customize their control valve ball valve setups, facilitating automation and remote management in many cases. By incorporating these components, systems can achieve smoother operation and more precise control, adapting effectively to specific application requirements.

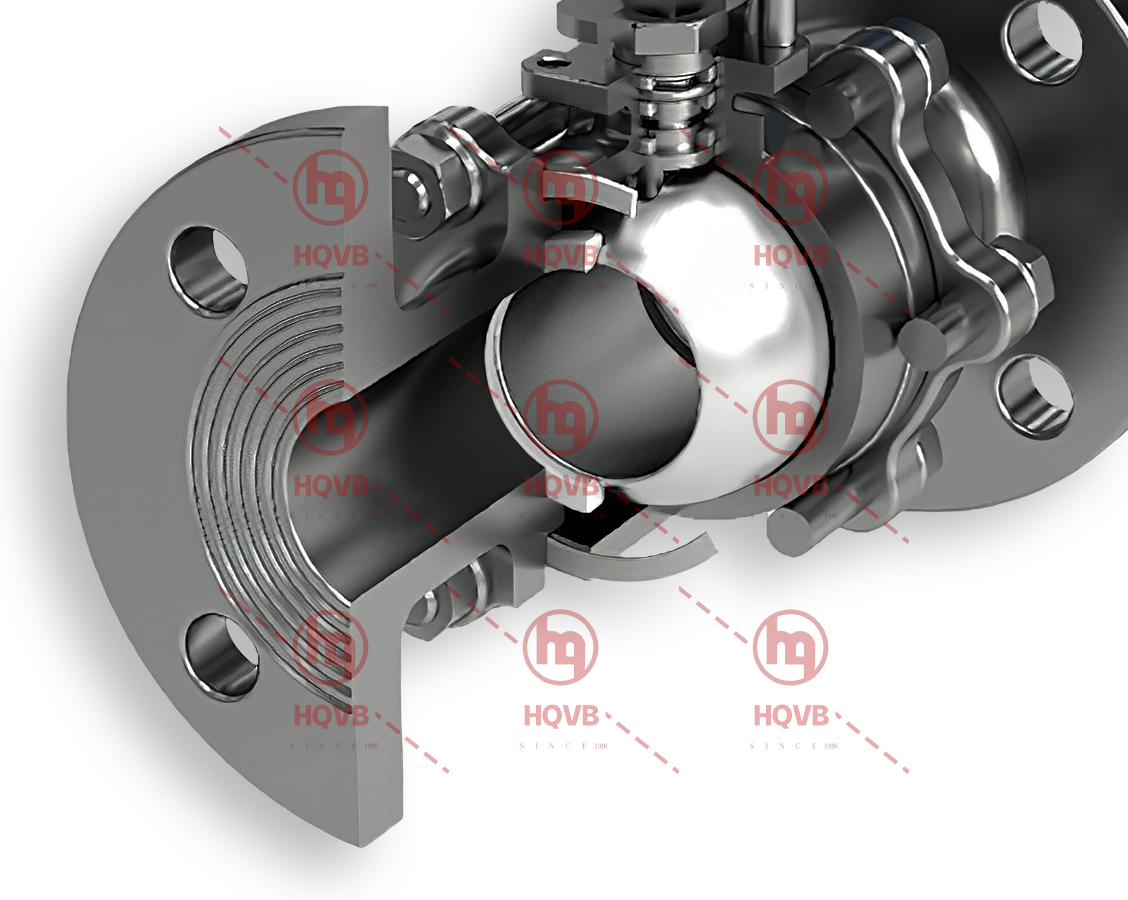

A key part of the ball valve assembly is the ball valve ball itself, which is responsible for the primary function of flow regulation. The ball valve ball operates within the valve body to either allow or restrict fluid passage. Advances in the materials and manufacturing processes of the ball valve ball have enhanced durability and resistance to wear, which is critical in demanding environments. Improved surface finishes and precision machining contribute to reduced leakage and consistent sealing performance, supporting longer service life for the entire valve assembly.

Components of ball valve designs have also seen improvements that complement the benefits brought by accessories. These components include the valve body, seats, stem, and seals. Each element works in unison with the ball valve ball to ensure reliable shutoff and efficient flow control. Innovations in seat materials and stem sealing techniques have lessd friction and leakage, which in turn reduces maintenance frequency. These enhancements, when combined with advanced ball valve accessories, provide a more robust and adaptable control valve ball valve solution.

The versatility of ball valve accessories means they can be tailored to different industries and system sizes. For instance, in process industries such as chemical and petrochemical, the ability to automate ball valve operation through electric or pneumatic actuators is essential. These accessories enable operators to regulate flow remotely, integrate valves into control systems, and monitor valve status through position feedback devices. This level of control improves operational safety and efficiency, especially in hazardous or hard-to-reach locations.

Furthermore, the modular nature of many ball valve accessories allows for easier upgrades and retrofits. Systems equipped with basic ball valves can be enhanced by adding suitable accessories without the need for complete replacement. This flexibility reduces downtime and capital expenditure, making it a practical approach for evolving operational demands. As a result, operators can maintain system performance and adapt to new process conditions with small disruption.

In addition to operational improvements, ball valve accessories contribute to maintenance and troubleshooting. Devices such as limit switches and solenoid valves provide critical feedback and control signals, helping maintenance teams identify issues promptly. The improved diagnostics capability reduces unplanned shutdowns and extends the lifecycle of the ball valve ball and other components of ball valve assemblies. Proactive maintenance supported by these accessories contributes to higher system availability.

Overall, the progress in ball valve accessories is shaping a new generation of control valve ball valve systems that are more flexible and easier to manage. By combining enhanced components of ball valve design with a range of accessories, users can achieve tailored solutions suited to various industrial needs. These developments support more efficient process control and offer adaptability as operational requirements change.

The continuous improvement of ball valve accessories, alongside advancements in the ball valve ball and other components of ball valve assemblies, is enhancing system flexibility. These innovations help deliver more reliable, customizable, and maintainable valve systems. As industries evolve, the role of ball valve accessories in optimizing control valve ball valve performance becomes increasingly important in supporting efficient and adaptable fluid management solutions.