As industries continue to evolve, the demand for durable, efficient, and precisely engineered flow control solutions remains steady. In response to the growing needs of manufacturers, OEMs, and bulk buyers, we are proud to announce that our brass ball valve components are now available for bulk orders. These components are manufactured to support a variety of systems, including ball valve control valve mechanisms, water flow control ball valve applications, and high pressure ball valve seating solutions.

The Role of Brass in Ball Valve Manufacturing

Brass has long been used in valve manufacturing due to its corrosion resistance, strength, and machinability. Our brass ball valve components are crafted to meet the functional requirements of both residential and industrial applications. Whether the system operates under moderate pressure or requires components for high pressure ball valve seating, brass continues to be a dependable material choice.

In the context of flow control, brass provides a balanced performance, offering adequate tensile strength while maintaining reliable formability. This makes it suitable for components like valve bodies, stems, seals, and threads. These parts are essential in ball valve control valve assemblies where reliable actuation and sealing are critical.

Applications in Water Flow Control Systems

A major area where these brass components excel is in water flow control ball valve assemblies. From municipal infrastructure and commercial plumbing to irrigation and industrial processing, the ability to precisely manage water flow is critical. The use of precision-machined brass balls, paired with properly matched seats, ensures smooth operation and less leak risks.

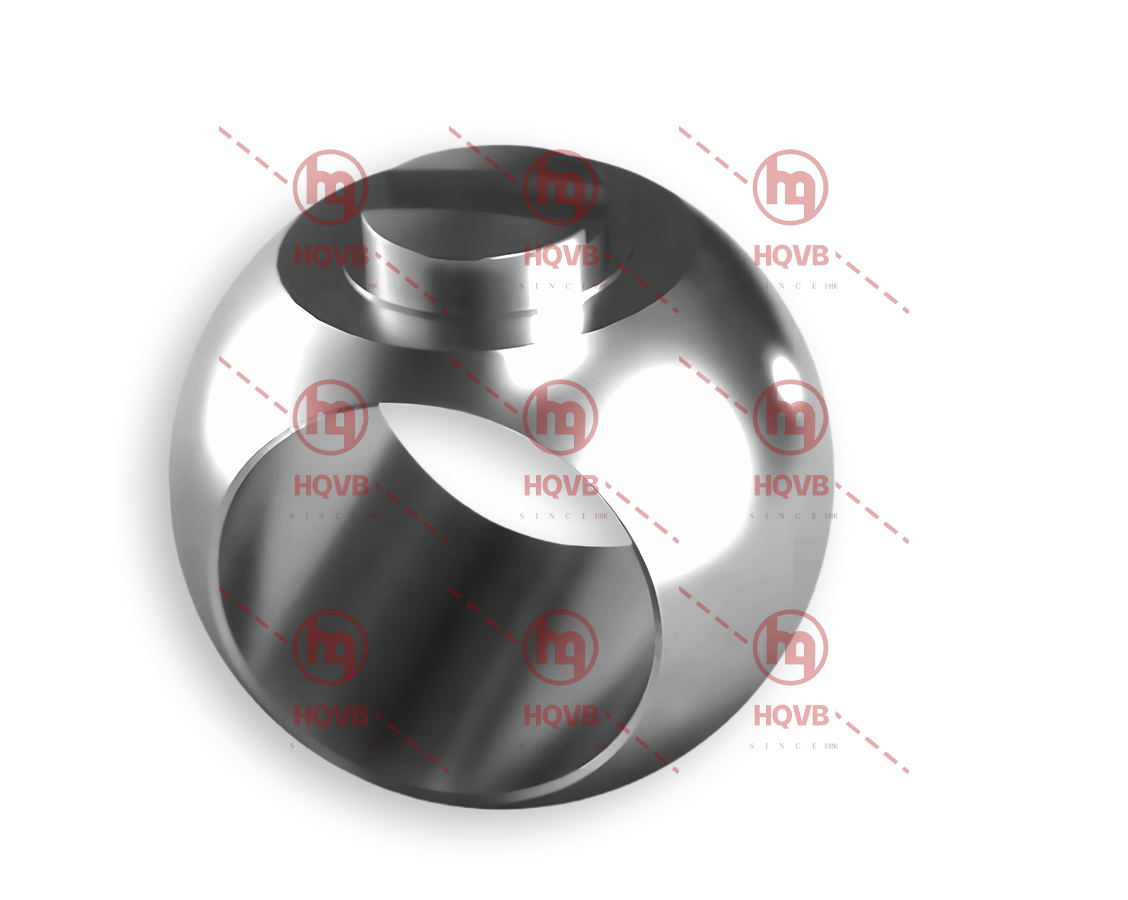

The uniformity of the ball surface is essential in maintaining the integrity of the flow path. Combined with PTFE or reinforced seats, brass balls help create a tight seal, allowing for controlled shut-off or modulation. These capabilities make brass ball valve components a common choice in water flow systems requiring dependable and cost-effective solutions.

Ball Valve Control Valve Assemblies

Control valves serve as vital components in fluid regulation across various industries. A ball valve control valve utilizes a spherical disc to regulate flow through the valve body. The quarter-turn actuation and tight sealing capabilities make ball valves a simple yet reliable control device.

In such assemblies, brass components play various roles. The body houses the ball, while the stem connects to the actuator or handle. Our brass stems and balls are machined with high precision to reduce torque requirements and improve sealing performance. When integrated into control valve systems, these components help maintain consistent performance, even during extended use or in demanding environments.

Additionally, our brass ball valve components can be customized to accommodate different control valve types—manual, electric, or pneumatic. Each configuration is supported by robust threading, machining, and tolerance controls that ensure compatibility with global plumbing and piping standards.

High Pressure Ball Valve Seating

In systems that operate under elevated pressure, the reliability of the valve seat becomes a critical concern. Our brass components are designed to support high pressure ball valve seating by offering a strong base structure for seat inserts. The seat plays a major role in maintaining sealing under pressure, reducing leakage, and ensuring consistent shut-off.

We work with seat materials that complement the brass body and ball, such as PTFE, graphite-reinforced polymers, or metal-backed elastomers. The brass casing for these seats offers mechanical support and dimensional stability, preventing deformation during pressure fluctuations.

Moreover, the interface between the brass seat housing and the sealing surface is engineered for small wear. In high-pressure applications such as gas lines, steam systems, and hydraulic circuits, these considerations contribute to the reliability and safety of the entire flow system.

Bulk Orders and Production Capabilities

We have streamlined our production lines to accommodate bulk requirements for both standard and custom brass ball valve components. Whether you are sourcing for ball valve control valve systems, water flow control ball valve applications, or high pressure ball valve seating, we provide a stable supply chain with consistent quality control.

All components undergo multi-stage inspection, including dimensional verification, leak testing, and pressure endurance analysis. Our goal is to deliver components that align with your exact technical drawings and specifications.

We welcome inquiries for large-volume orders and offer flexible packaging and labeling services. Our engineering team is available to support custom development for specific valve assemblies and to ensure compatibility with your system requirements.

With a focus on reliability, material strength, and design precision, our brass ball valve components are a solid foundation for building or maintaining fluid control systems. Now available for bulk orders, these components are engineered to support a wide range of applications, including water management, gas systems, and pressure-regulated networks.

Contact our sales team today to discuss your procurement needs or request samples for your evaluation process. Let us be your trusted source for high-quality valve components built to perform under a variety of operational conditions.