In various industries, ball valves serve as a reliable solution for controlling the flow of liquids and gases. Whether in chemical processing, oil and gas, water treatment, or marine systems, the demand for durable and corrosion-resistant components continues to rise. Among the materials available, stainless steel stands out for its mechanical strength, resistance to harsh environments, and long-term service life. This article explores the critical components of stainless steel ball valve parts—especially the ball stem valve, standard ball valve, and the ball and seat assembly—and their roles in meeting performance requirements in demanding applications.

Understanding the Structure of Stainless Steel Ball Valves

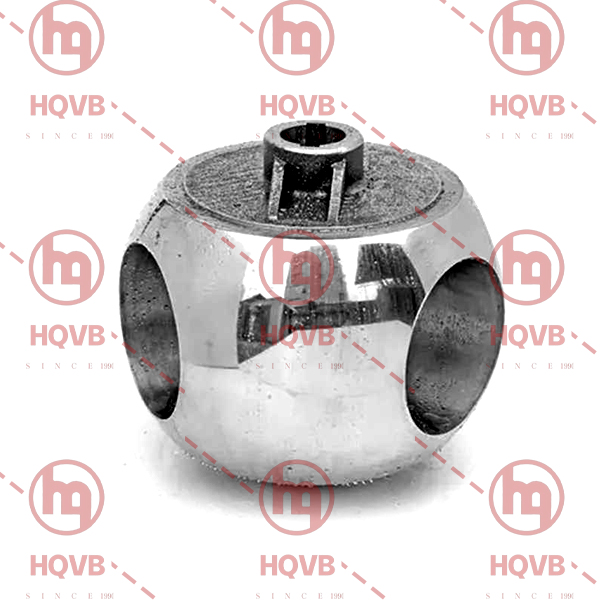

A stainless steel ball valve typically consists of a spherical ball, a stem, a body casing, seals, and seats. Each part plays a unique role in ensuring smooth operation and flow control.

The standard ball valve is one of the more widely used configurations. It features a full-bore or reduced-bore design with a hollow, pivoting ball placed inside the valve body. When the handle or actuator turns the ball, the valve either opens or closes, allowing or preventing flow. The standard design is favored for its straightforward functionality and small pressure drop across the valve in the open position.

Stainless steel, with grades like SS304 and SS316, is frequently selected for its compatibility with aggressive media and resistance to rust and pitting corrosion. This makes stainless steel ball valves suitable for both indoor and outdoor use, including corrosive and high-temperature environments.

The Importance of the Ball Stem Valve

The ball stem valve is a critical component that connects the ball to the actuator or manual handle. It transmits the torque necessary to rotate the ball within the valve body. The stem must be designed to handle mechanical stress, pressure fluctuations, and temperature changes without distortion or failure.

In stainless steel ball valves, the stem is often manufactured from the same grade of steel as the valve body to maintain uniform resistance and mechanical properties. A secure connection between the stem and the ball is essential for consistent rotation and sealing, particularly in high-cycle or automated applications.

Moreover, the stem sealing system is vital to prevent leaks. It usually incorporates O-rings or packing rings made of PTFE or other heat-resistant materials. A properly engineered ball stem valve ensures safe operation even under varying operational pressures and flow conditions.

Role of the Ball and Seat in Flow Control

The ball and seat assembly is the core of any ball valve’s functionality. The ball acts as the closure element, while the seats provide the sealing interface. Together, they regulate the fluid flow with a simple quarter-turn motion.

In stainless steel valves, the ball is often precision-machined and polished to ensure a smooth surface, which improves sealing capability and reduces wear over time. The seats are typically made from thermoplastic materials such as PTFE, TFM, or PEEK, chosen based on the fluid properties and temperature range.

The combination of a stainless steel ball and engineered seat materials offers stable performance over extended periods. In abrasive or high-pressure environments, reinforced seat materials may be used to less deformation or leakage.

The tolerance between the ball and seat is carefully designed to ensure a tight seal when the valve is closed, while also allowing smooth rotation during operation. In applications involving slurry, gas, or corrosive fluids, the durability and sealing integrity of the ball and seat become even more important.

Applications and Advantages

Stainless steel ball valve parts are utilized across a wide range of industries due to their versatility and strength. Some of the key applications include:

Chemical processing: Stainless steel’s resistance to a variety of acids and solvents makes it ideal for regulating hazardous fluids.

Oil and gas: In upstream and downstream operations, ball valves manage high-pressure and high-temperature conditions with reliability.

Water and wastewater treatment: The non-reactive nature of stainless steel ensures long service life in systems dealing with both potable water and wastewater.

Pharmaceutical and food industries: Hygiene, cleanliness, and material integrity are crucial, and stainless steel meets these requirements.

In each case, the ball stem valve, standard ball valve, and ball and seat work together to deliver reliable flow control, resist wear, and less downtime due to maintenance.

Stainless steel ball valve parts are essential components in numerous industrial systems requiring strength, reliability, and resistance to environmental stress. The integration of the ball stem valve, standard ball valve, and ball and seat assemblies contributes to consistent performance even under challenging operational conditions. As industries continue to demand dependable solutions, the role of precision-engineered stainless steel valve components remains significant in ensuring system safety and efficiency.