In modern industrial operations, fluid control systems often operate in challenging environments—from frigid low-temperature settings to high-pressure pipelines, and from corrosive chemical workflows to vibration-intensive machinery. These extreme conditions place unprecedented demands on sealing components, making the Hard Seal Ball a critical factor in ensuring system stability. To meet these needs, manufacturers have shifted from "one-size-fits-all" designs to targeted adaptive optimizations, refining every aspect of the Hard Seal Ball—from material selection to structural design—to ensure reliable performance even in the harshest operating scenarios. This focus on adaptability not only reduces operational risks but also strengthens the role of Hard Seal Balls as a cornerstone of resilient fluid control systems.

Temperature fluctuations pose a major threat to traditional sealing components: low temperatures can make materials brittle and prone to cracking, while high temperatures may cause softening or deformation, leading to leaks. Hard Seal Balls address this challenge through specialized thermal adaptation strategies. For low-temperature applications, manufacturers integrate anti-brittle additives into alloy formulations, ensuring the ball retains flexibility and structural integrity even in near-freezing conditions. For high-temperature workflows, heat-resistant ceramics or high-temperature alloys replace conventional materials, preventing thermal expansion-induced misalignment or seal failure. These temperature-specific optimizations mean Hard Seal Balls can maintain consistent sealing performance across a wide range of thermal extremes, eliminating the need for frequent replacements due to temperature-related damage.

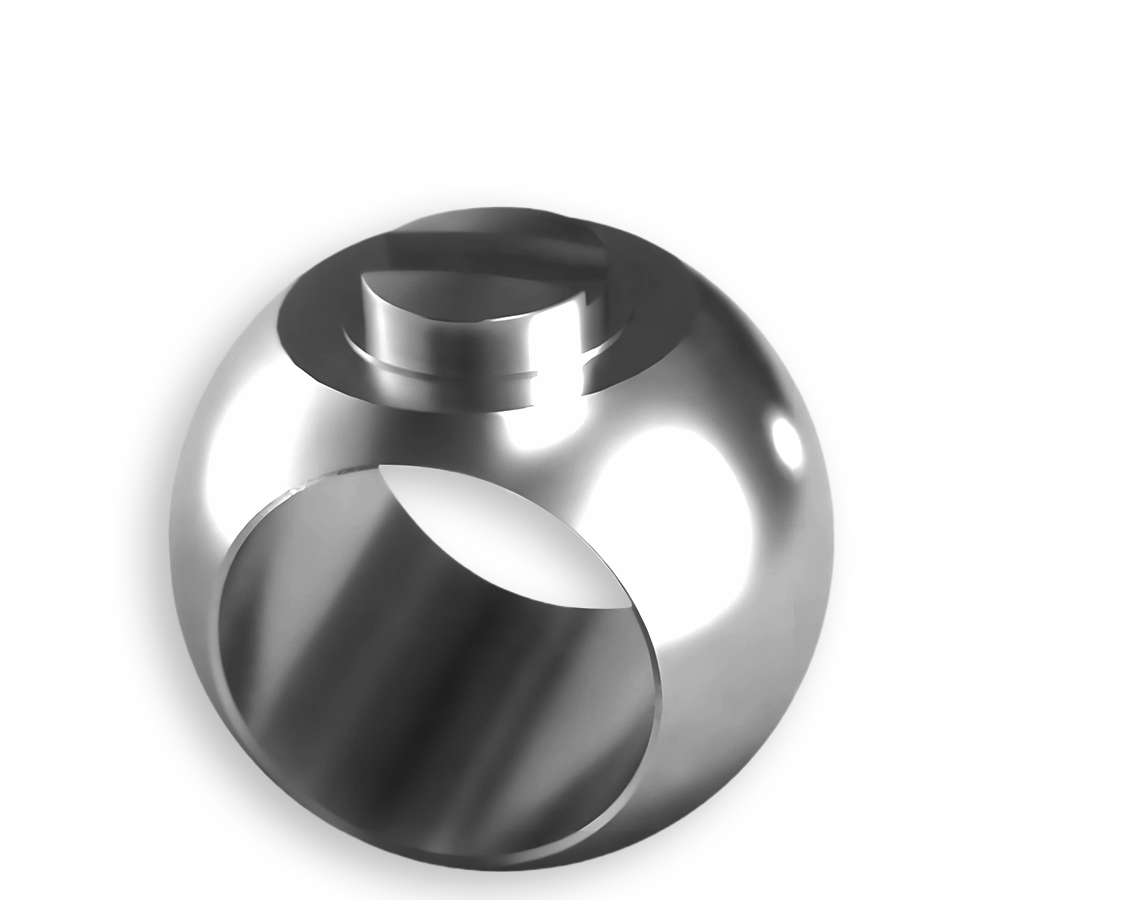

High-pressure fluid systems—common in oil and gas, hydraulic machinery, and industrial processing—require sealing components that can withstand intense force without compromising integrity. Hard Seal Balls for these scenarios undergo targeted structural enhancements to boost sealing stability. First, the spherical surface is engineered for ultra-high precision, ensuring maximum contact with sealing seats and minimizing gaps that could lead to pressure-induced leaks. Second, the ball’s core structure is reinforced with high-strength materials, preventing deformation under extreme pressure. Additionally, some designs incorporate pressure-compensating features that adjust to fluctuations in system pressure, maintaining a tight seal even when pressure spikes occur. These structural refinements make Hard Seal Balls a reliable choice for high-pressure applications, where even minor leaks can lead to costly downtime or safety hazards.

Corrosive substances—such as acids, alkalis, and industrial solvents—can rapidly degrade traditional sealing materials, leading to premature failure and contamination risks. To combat this, Hard Seal Ball manufacturers now offer customized chemical compatibility solutions tailored to specific workflow needs. For acidic environments, ceramic or fluoropolymer-based Hard Seal Balls are used, as these materials resist acid erosion and maintain structural integrity over time. For alkaline or solvent-heavy systems, specialized alloy blends with anti-corrosive coatings are deployed, preventing chemical reactions that weaken the ball’s surface. By matching the Hard Seal Ball’s material composition to the specific chemicals in a system, manufacturers eliminate corrosion-related wear, extending the component’s lifespan and ensuring the purity of the fluid being controlled.

Vibration and mechanical impact—common in mining, construction, and heavy machinery—can loosen seals, shift components, and disrupt fluid flow. Hard Seal Balls for these environments feature structural reinforcement designed to withstand dynamic stress. The ball’s connection points to the valve system are strengthened with shock-absorbing materials, reducing the transfer of vibration to the sealing surface. Additionally, the spherical shape is optimized for stability, minimizing movement even when the system is subjected to sudden impacts. Some designs also include anti-loosening features that lock the ball in place during operation, preventing misalignment caused by vibration. These enhancements ensure that Hard Seal Balls remain securely sealed and functional, even in high-vibration or high-impact industrial settings.