In today’s industrial landscape, where fluid control systems demand heightened reliability, minimal leakage, and reduced downtime, the Hard Seal Ball has emerged as a critical component—one whose performance is increasingly elevated by cutting-edge manufacturing techniques. These advanced methods enable precise control over both material properties and structural precision, addressing the stricter operational requirements of global factories. As industrial reliance on robust fluid management grows, innovations in Hard Seal Ball manufacturing have become a key driver of confidence in product quality, ensuring these components meet the evolving needs of modern industry.

Gone are the days when Hard Seal Balls relied solely on traditional stainless steel. Today, specialized alloys, ceramics, and composite materials have expanded the component’s capability to tackle longstanding industrial challenges. These new materials are engineered to address specific pain points: from resisting the corrosive effects of harsh chemical environments to withstanding the abrasive forces of heavy-duty material handling. By moving beyond one-size-fits-all stainless steel, manufacturers can now tailor Hard Seal Balls to match the unique demands of their operations—whether that means enduring extreme chemical exposure or maintaining integrity under high-wear conditions. This material versatility has transformed the Hard Seal Ball from a basic part into a adaptive solution, aligned with the varied needs of modern industrial workflows.

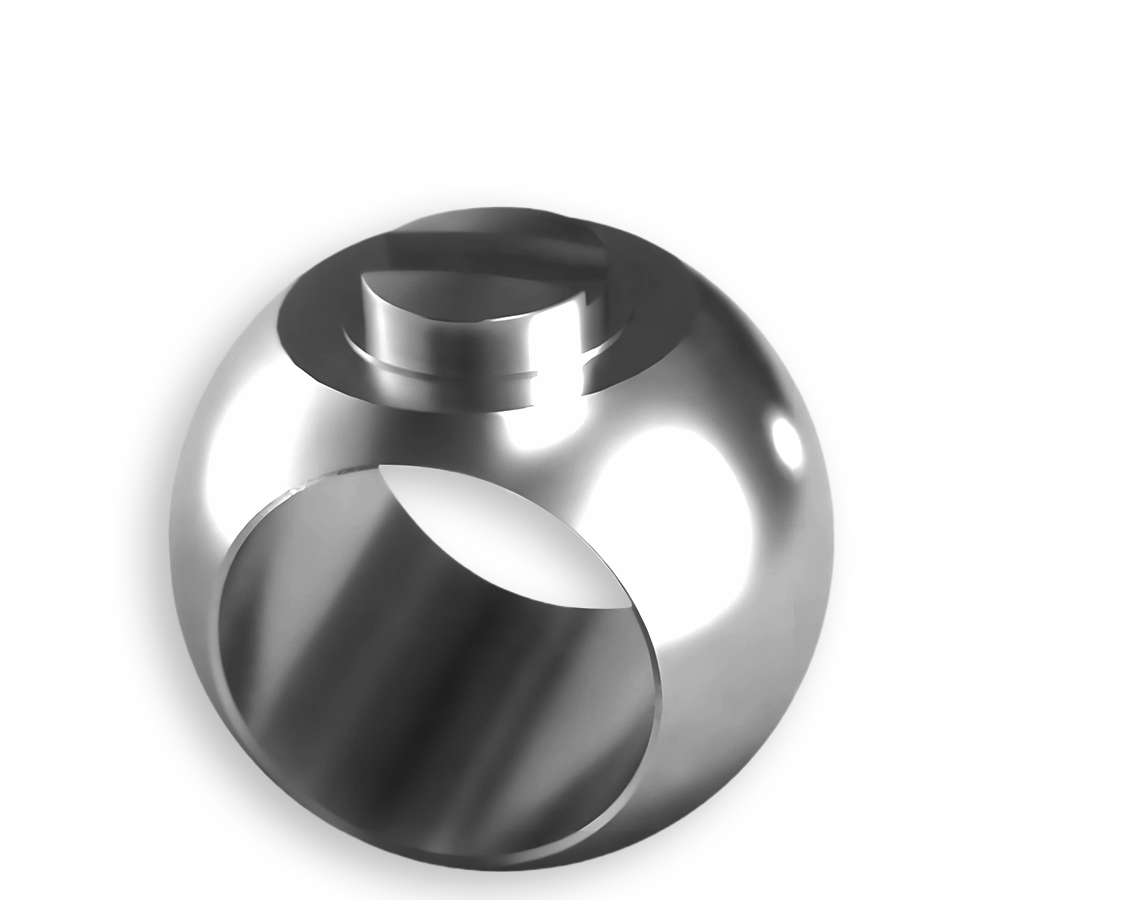

Modern manufacturing equipment has revolutionized the precision of Hard Seal Ball production, enabling levels of accuracy that directly translate to better fluid system performance. The tight tolerances and ultra-smooth surfaces achieved through advanced machining ensure a seamless, leak-proof fit within fluid control systems—critical for maintaining consistent operation. This precision also delivers unmatched consistency across every Hard Seal Ball produced, eliminating the need for time-consuming sorting or adjustments during replacement. For industrial teams, this means faster, more efficient maintenance: components can be installed directly, with no guesswork about fit or function. In an era where operational efficiency is paramount, this level of machining precision turns the Hard Seal Ball into a tool for streamlining workflows, not disrupting them.

Surface finishing processes have become a vital step in optimizing Hard Seal Ball performance, with treatments designed to match the unique demands of different industrial settings. For environments where abrasion is a constant threat, protective coatings are applied to boost wear resistance, extending the component’s lifespan and reducing the frequency of replacements. For sectors where hygiene is non-negotiable, ultra-smooth polishing techniques create surfaces that resist residue buildup, simplifying cleaning and ensuring compliance with industry-specific sanitation standards. These targeted treatments do more than enhance durability—they ensure the Hard Seal Ball aligns with the specialized requirements of each application, whether that’s withstanding rough handling or meeting strict cleanliness guidelines.

No Hard Seal Ball leaves the manufacturing facility without undergoing a rigorous series of quality checks—protocols designed to guarantee performance and eliminate post-installation risks. These verification processes begin with dimensional inspections, confirming that every component meets exact specifications for shape and size. Next, performance testing simulates real-world industrial conditions, assessing how the Hard Seal Ball holds up under pressure, temperature fluctuations, and other operational stresses. Material validation is also a key step, ensuring that the components use only the specified, high-quality materials. The result? Industrial teams receive Hard Seal Balls that are ready for direct installation, with no need for additional testing or adjustments. This level of pre-delivery verification not only saves time but also builds trust, ensuring the component will perform as expected in critical fluid control systems.