Hard Seal Ball components are increasingly seen as key parts in industrial fluid systems—especially where standard parts can’t solve specific operational problems. As industries around the world focus on making processes more efficient and equipment last longer, the value of carefully designed sealing solutions has become more noticeable. This trend fits with the bigger shift toward custom, precise products in industrial manufacturing.

Different industrial fields have unique needs for how well seals work. For example, the chemical processing industry needs materials that won’t be damaged by harsh chemicals (like acids or solvents). If a seal breaks down here, it could cause leaks and stop production. On the other hand, oil and gas operations need components that can handle high pressure (like in pipeline transport) and extreme heat (such as in oil refineries). Even the food processing industry has special demands—seals here need to be easy to clean and not leave any gaps where bacteria can grow, to keep food safe. Hard Seal Ball products can be made with materials and designs that fit each of these needs, making sure systems run reliably no matter the industry.

Industrial processes work under all kinds of tough conditions—some have high pressure, some extreme heat, and others use chemicals that eat away at regular materials. Hard Seal Ball components are made with materials picked just for these situations. For instance, if a factory uses high-temperature steam (like in power plants), the seals might be made from heat-resistant alloys that don’t warp or break down. If a plant handles corrosive chemicals (like in fertilizer production), the seals could be made from ceramic or special stainless steel that resists rust and damage. Choosing the right material means the seals work better and last longer, even when things get tough.

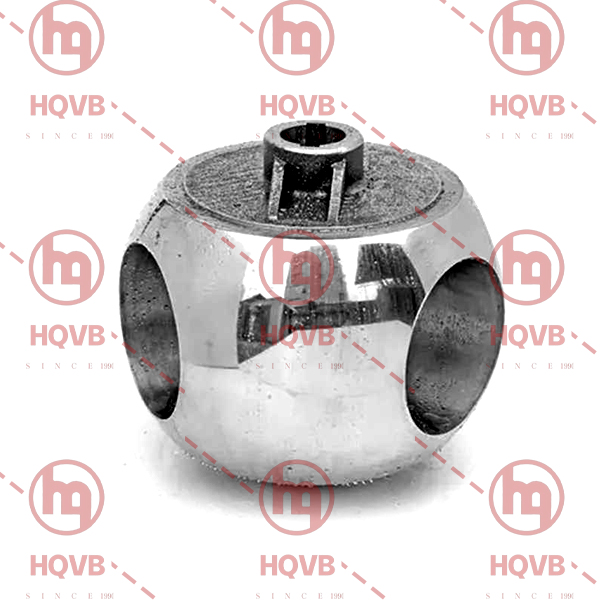

How accurate a seal’s size is and how smooth its surface is matter a lot for two things: stopping leaks and controlling fluid flow. Hard Seal Ball products are made with very precise measurements—so they fit perfectly with other parts of the system. This tight fit helps reduce leaks: for example, in a pharmaceutical factory, even a tiny leak could contaminate medicines, so precise seals keep production safe. It also makes fluid flow easier to control: in a water treatment plant, being able to adjust flow exactly helps save energy and keep water clean. This precision makes the whole system work better, especially in processes where small mistakes affect product quality or energy use.

Many old industrial facilities need to replace parts—but they don’t want to buy entirely new systems (which is expensive). Hard Seal Ball solutions can be made to match the old equipment’s specs. For example, a 30-year-old power plant might have valves that still work, but their seals are worn out. Instead of replacing the whole valve, they can get custom Hard Seal Balls that fit the old valve perfectly. This not only saves money but also cuts down on downtime—since replacing a seal is faster than installing a new valve. It gives factory operators more flexibility to keep their equipment running without overspending on upgrades.