Industrial operations involving high-pressure pipelines, chemical reactors, and energy facilities require components that can withstand intense operational conditions. Hard Seal Balls and Custom Ball Valve Balls are increasingly recognized as essential for maintaining system stability and minimizing risks. Buyers today are looking for valve solutions that combine durability, precision, and reliability to ensure smooth operations. Online professional forums and technical social media discussions have highlighted real-world case studies, making it easier for engineers to identify components that deliver consistent performance under demanding conditions.

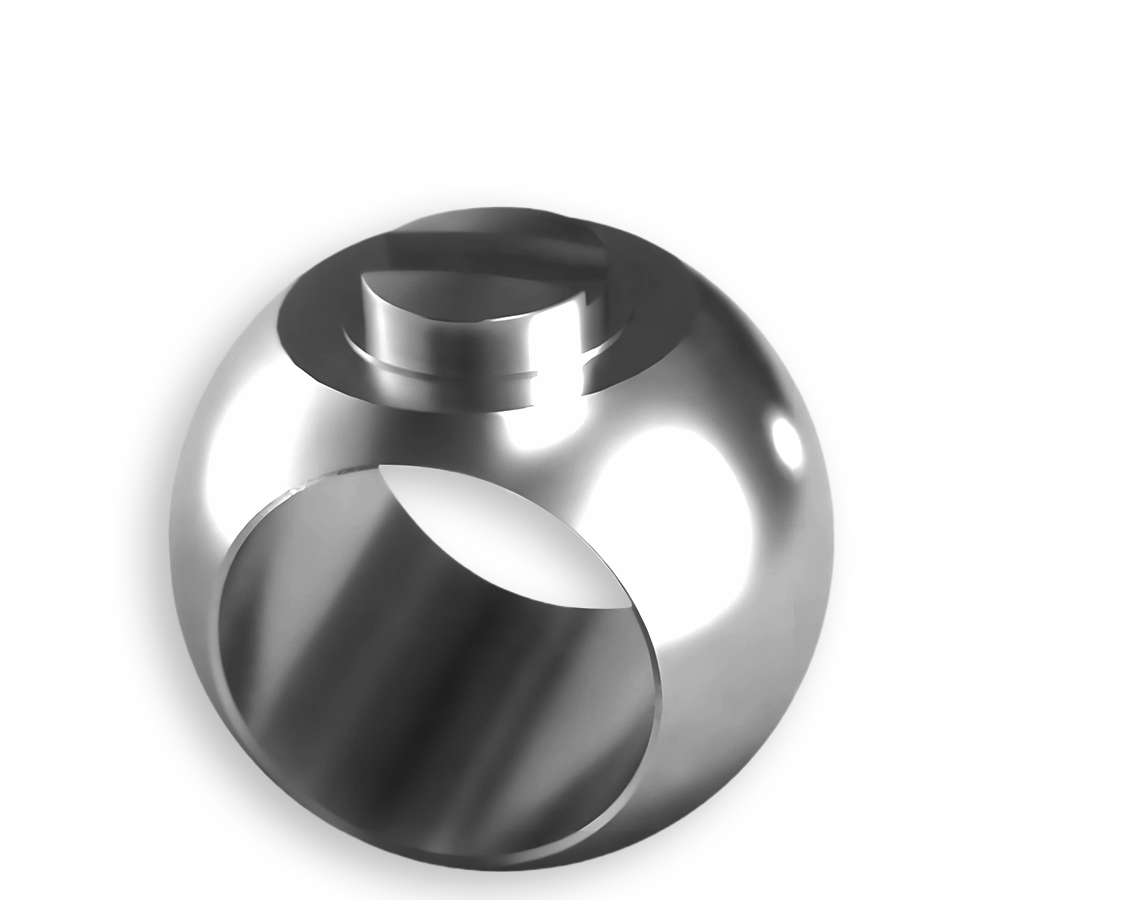

One of the main challenges in high-pressure systems is maintaining a tight seal to prevent leaks. Hard Seal Balls are engineered with high-strength materials and advanced surface treatments that resist wear, corrosion, and deformation. Their precision tolerances ensure optimal sealing performance, even in fluctuating pressure conditions. Facilities that integrate Hard Seal Balls report fewer maintenance issues, enhanced safety, and improved operational efficiency. This makes them a trusted solution for industrial buyers seeking long-term reliability.

Every high-pressure system is unique, and standardized components often fail to meet specific operational demands. Custom Ball Valve Balls offer tailored solutions in terms of materials, coatings, and dimensions. Engineers can select configurations that match precise flow characteristics, temperature ranges, and chemical compatibility. This customization ensures consistent performance, reduces the risk of operational failures, and allows industrial facilities to optimize system efficiency. Buyers increasingly prefer custom solutions to meet both safety standards and operational goals.

Modern manufacturing technologies, including CNC machining, multi-layer coatings, and digital inspection systems, have revolutionized the production of Hard Seal Balls and Custom Ball Valve Balls. Precision engineering ensures that each component meets exact specifications, enhancing durability, sealing efficiency, and operational stability. Automated quality checks and real-time monitoring allow manufacturers to deliver consistent, high-performance products. These innovations also support global compliance standards, which are increasingly important for industrial buyers.

Engineers and industrial professionals are sharing their experiences on LinkedIn, technical blogs, webinars, and YouTube demonstrations. Peer reviews, maintenance case studies, and performance comparisons have become valuable resources for buyers evaluating Hard Seal Balls and Custom Ball Valve Balls. These digital discussions help identify which products offer superior durability, sealing reliability, and adaptability for high-pressure systems. The transparency and accessibility of shared insights influence global procurement decisions and encourage manufacturers to maintain high-quality standards.

Emerging markets in Southeast Asia, the Middle East, and Latin America are rapidly expanding infrastructure, energy production, and chemical processing facilities. These regions require reliable valve components capable of performing under intense operating conditions. Hard Seal Balls and Custom Ball Valve Balls provide the precision, durability, and operational reliability necessary to support high-pressure systems. Suppliers offering tailored solutions and robust technical support gain a competitive advantage, as global buyers increasingly seek components that can meet exacting specifications.

As industrial systems evolve and high-pressure operations become more demanding, Hard Seal Balls and Custom Ball Valve Balls have become indispensable components. Their precise engineering, durability, and customizable features ensure reliable sealing, operational efficiency, and enhanced system safety. Industrial buyers recognize the strategic value of investing in these advanced valve components, which reduce downtime, improve maintenance schedules, and support long-term operational stability. Together, Hard Seal Ball and Custom Ball Valve Balls are defining the next generation of high-performance solutions for demanding industrial applications worldwide.