In today’s industrial environment, Hard Seal Balls and Custom Ball Valve Balls are taking center stage as components that directly impact operational safety. Facilities in sectors such as chemical processing, oil and gas, and water treatment face increasingly stringent safety requirements. Buyers are paying closer attention to the quality and reliability of valve components, ensuring that each element contributes to leak prevention, pressure stability, and long-term durability. Social media discussions, professional webinars, and technical forums have amplified awareness, helping engineers identify which products deliver measurable safety improvements.

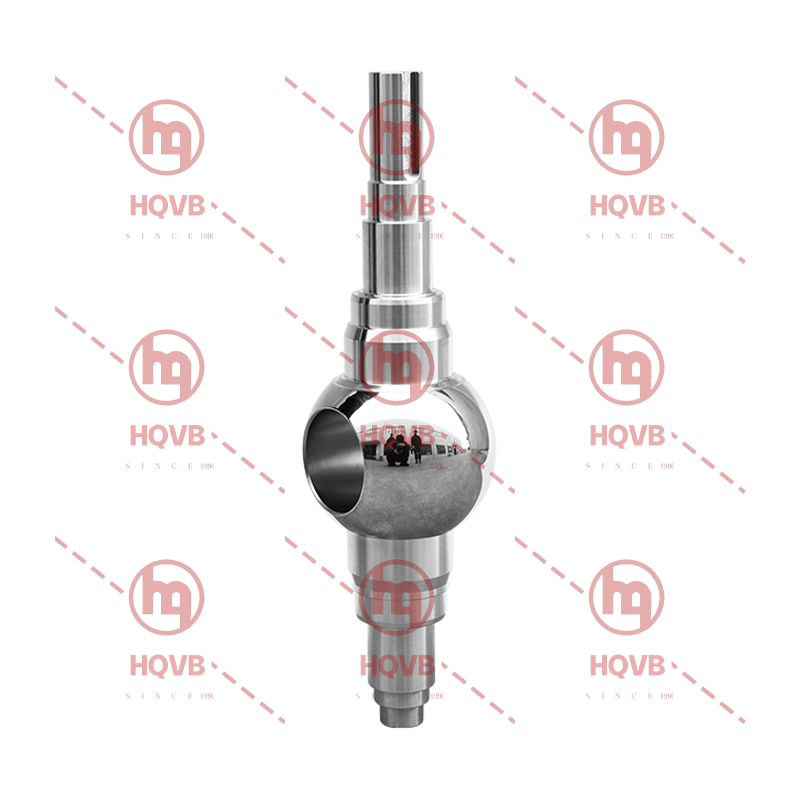

High-pressure pipelines and complex fluid systems are prone to wear, corrosion, and leakage. Hard Seal Balls are designed to withstand these challenging conditions, providing reliable sealing performance that reduces the risk of system failures. Their wear-resistant surfaces maintain smooth operation even under continuous cycles, while precise tolerances ensure minimal leakage. By integrating Hard Seal Balls, industrial facilities can maintain safer operations, reduce downtime, and protect both equipment and personnel from hazards associated with uncontrolled fluid release.

Every industrial system has unique requirements, and one-size-fits-all solutions often fail to meet operational standards. Custom Ball Valve Balls allow engineers to specify materials, coatings, and dimensions that suit exact application conditions. Tailored solutions ensure compatibility with automated control systems, pressure variations, and extreme temperatures. By optimizing performance to the system’s specific needs, Custom Ball Valve Balls enhance safety, efficiency, and reliability, offering buyers the confidence that each installation will perform as expected over the long term.

Durability and safety are closely linked in industrial applications. Components that degrade quickly can compromise system integrity, leading to leaks, pressure drops, and unplanned shutdowns. Hard Seal Balls and Custom Ball Valve Balls employ advanced surface treatments and high-strength alloys to resist wear and corrosion. Their long-lasting performance ensures consistent operation, reducing the likelihood of mechanical failure and enhancing overall system resilience. Buyers increasingly recognize that investing in durable valve components is a proactive safety measure rather than a reactive fix.

Technical discussions on platforms like LinkedIn, YouTube, and industry-specific forums have become invaluable for buyers seeking reliable products. Engineers share insights on real-world performance, maintenance experiences, and product comparisons. These digital interactions allow potential buyers to see how Hard Seal Balls and Custom Ball Valve Balls perform under various operational conditions. The transparency provided by online resources helps procurement teams make informed decisions, ensuring that safety and reliability remain central to industrial operations.

Emerging industrial markets—especially in Southeast Asia, the Middle East, and Latin America—are seeing increasing demand for high-quality valve components. Expanding petrochemical plants, energy facilities, and water infrastructure projects require products that combine precision, durability, and safety. Suppliers offering tailored solutions, such as Custom Ball Valve Balls, are well-positioned to meet these needs. Online technical communities and social media further amplify product awareness, allowing manufacturers to connect with buyers seeking reliable, safe, and efficient solutions.

As industrial systems become more complex and safety requirements grow, Hard Seal Ball and Custom Ball Valve Balls are emerging as essential components. Their durability, precision, and ability to be customized ensure consistent sealing, pressure stability, and operational reliability. By investing in these advanced products, buyers not only enhance safety but also improve efficiency and reduce maintenance challenges. Manufacturers who focus on high-quality design, precision engineering, and documented performance will continue to meet global industrial demand, reinforcing the strategic importance of Hard Seal Balls and Custom Ball Valve Balls in modern industrial projects.