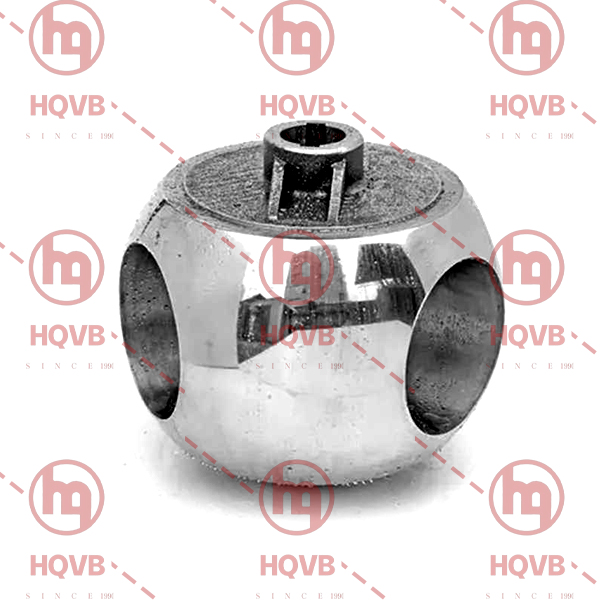

In modern industrial applications, Hard Seal Balls and Custom Ball Valve Balls have become central to ensuring reliable and efficient fluid control. Facilities worldwide are seeking components that can maintain consistent performance in demanding environments such as chemical processing, energy production, and water treatment. Buyers are increasingly prioritizing durability, precision, and compatibility with automated monitoring systems. With the rise of social media technical discussions, buyers now evaluate products not only on material strength but also on long-term operational benefits.

Industrial systems now operate for extended periods without downtime, and traditional components often fail to meet these expectations. High-quality Hard Seal Balls provide resistance to wear, pressure fluctuations, and corrosion, ensuring smooth operation over long service cycles. Similarly, Custom Ball Valve Balls offer tailored solutions that match specific system requirements, allowing facilities to reduce maintenance needs and improve operational efficiency. Professionals increasingly recognize that investing in durable components leads to cost savings and fewer unplanned interruptions.

With energy costs and sustainability concerns on the rise, many industrial buyers are looking for solutions that optimize fluid dynamics. Valve balls with precise geometries reduce turbulence, minimize pressure drops, and ensure smoother flow. This not only saves energy but also enhances the lifespan of pumps, compressors, and other downstream equipment. Online engineering forums highlight case studies demonstrating the tangible benefits of high-precision valve components in energy-efficient systems, emphasizing the importance of well-engineered Hard Seal Balls and Custom Ball Valve Balls.

Manufacturers are integrating advanced CNC machining, multi-layer coatings, and digital inspection systems to produce more consistent and reliable valve balls. These innovations allow suppliers to meet stringent international standards while delivering components that adapt to diverse industrial scenarios. Buyers are increasingly drawn to products backed by precise manufacturing records, real-time quality checks, and documented performance guarantees. Social media platforms and professional networks provide an ongoing dialogue between manufacturers and end users, driving continuous improvement in design and material science.

The rise of LinkedIn engineering groups, industry-specific webinars, and technical YouTube channels allows buyers to access firsthand insights into valve performance. Peer reviews, maintenance reports, and video demonstrations influence purchasing decisions, enabling buyers to compare Hard Seal Balls and Custom Ball Valve Balls across suppliers and applications. Transparent online interactions encourage manufacturers to maintain high standards while also providing customers with confidence that their investment will meet long-term operational goals.

Regions with rapidly growing industrial sectors, such as Southeast Asia, India, and parts of the Middle East, are driving demand for premium valve components. Expanding energy infrastructure, petrochemical plants, and large-scale water-treatment projects require products that combine high durability, precision engineering, and energy-efficient design. Suppliers offering tailored solutions for these markets find ample opportunity to establish their brand and reputation for reliability. Social media and digital networking continue to amplify awareness, further increasing demand for high-quality Hard Seal Balls and Custom Ball Valve Balls.

As industrial systems become more complex, Hard Seal Balls and Custom Ball Valve Balls are no longer optional—they are vital components for safe, efficient, and long-lasting operations. Their combination of precision engineering, durability, and operational efficiency ensures they meet global buyer expectations. Manufacturers who innovate in materials, design, and quality assurance will continue to attract buyers seeking reliable solutions that enhance performance while minimizing maintenance. The global industrial community increasingly recognizes these components as strategic investments that support long-term operational success.