This article explores common quality testing methods used for ball valve components, with a particular focus on components such as the HP ball valve and the teflon seat ball valve, which have become increasingly common due to their durability and chemical resistance.

1. Visual Inspection

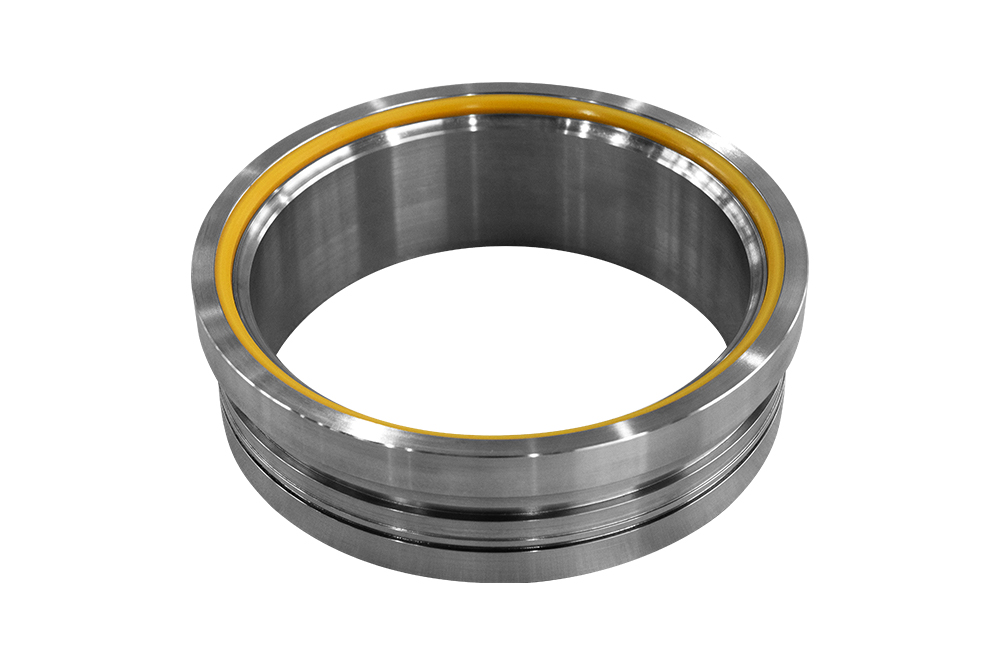

The one step in quality assurance typically involves a thorough visual inspection. This method helps identify obvious surface defects such as cracks, corrosion, or manufacturing irregularities. For ball valve components, especially the precision-machined ball and stem, any visible imperfection can advance to performance issues or leakage. In the case of teflon seat ball valves, the seat surface is carefully examined to ensure smoothness and uniformity, as irregularities here can affect sealing capability.

2. Dimensional Measurement

Dimensional accuracy is critical for the correct assembly and operation of ball valves. High-precision measuring tools like calipers, micrometers, and coordinate measuring machines (CMM) are employed to verify the dimensions of parts such as the valve ball, body bore, and stem diameter. This is especially important for HP ball valves, where high pressure demands tight tolerances to avoid leaks and maintain structural integrity.

CMM devices can measure complex geometries and provide detailed reports to confirm that components meet specified tolerances. Dimensional measurement ensures compatibility with mating parts and adherence to industry standards.

3. Pressure Testing

Pressure testing is a vital part of evaluating ball valve components for leakage and strength. Two common pressure tests are hydrostatic and pneumatic testing.

Hydrostatic Testing: This involves filling the valve with water and applying pressure above the valve’s rated limit. The test checks for leaks through the valve body, stem, and seat. It is particularly useful for validating the sealing performance of the Teflon seat ball valve, as the seat material must withstand pressure without deforming or leaking.

Pneumatic Testing: Using compressed air, this test checks for leaks and pressure resistance in a dry environment. It can detect smaller leaks that may not be evident in hydrostatic tests.

Both methods confirm the valve’s ability to hold pressure safely under operating conditions.

4. Leak Testing

Leak testing focuses specifically on detecting fluid or gas leakage in assembled ball valves. Apart from pressure testing, leak tests use various methods such as helium leak detection, bubble testing, and vacuum decay testing.

Helium Leak Detection: This sensitive method involves filling the valve with helium and using specialized detectors to identify minute leaks. It is suitable for critical applications where leakage tolerance is very low.

Bubble Testing: The valve is submerged in water or another liquid while pressurized air is introduced inside. Bubbles indicate leakage points. This simple method is effective for initial leak checks on HP ball valve assemblies.

Vacuum Decay Testing: The valve is placed in a vacuum chamber, and pressure changes are monitored to detect leaks.

Ensuring the leak-tightness of ball valves is particularly important for Teflon seat ball valves, as the soft seat material must maintain a secure seal without deterioration over time.

5. Material Testing

Material testing verifies the chemical composition and mechanical properties of ball valve components. This step ensures that the materials used can withstand the operational environment.

Spectroscopy Analysis: Techniques such as X-ray fluorescence (XRF) and optical emission spectrometry (OES) identify elemental composition and verify that alloys meet specifications.

Hardness Testing: Rockwell or Vickers hardness tests assess the strength and wear resistance of metals used in valve balls and stems.

Corrosion Testing: Accelerated corrosion tests, such as salt spray or cyclic corrosion tests, evaluate the durability of valve bodies and components exposed to harsh environments.

Material testing is essential for HP ball valves, which often operate under high pressure and temperature conditions, and for teflon seat ball valves, where chemical resistance of both the seat and metal parts is required.

6. Functional Testing

Functional testing simulates real operating conditions to check the performance of ball valves. This can include cycling the valve through open and closed positions to detect wear or sticking issues in the stem and ball.

For teflon seat ball valves, this test confirms the seat’s ability to provide reliable sealing after multiple cycles. Functional testing also ensures smooth rotation and responsiveness, which is important in automated or remote-controlled valve systems.

Quality testing methods for ball valve components are comprehensive and cover every stage from raw materials to finished products. Visual inspections, dimensional measurements, pressure and leak testing, material analysis, and functional checks all contribute to verifying that components like HP ball valves and teflon seat ball valves meet the necessary safety and performance standards.

Adopting rigorous quality testing not only reduces the risk of failure but also supports customer confidence in the reliability of valve components used across various industrial sectors. Consistent application of these testing methods forms a strong foundation for the manufacturing and supply of dependable ball valve assemblies.