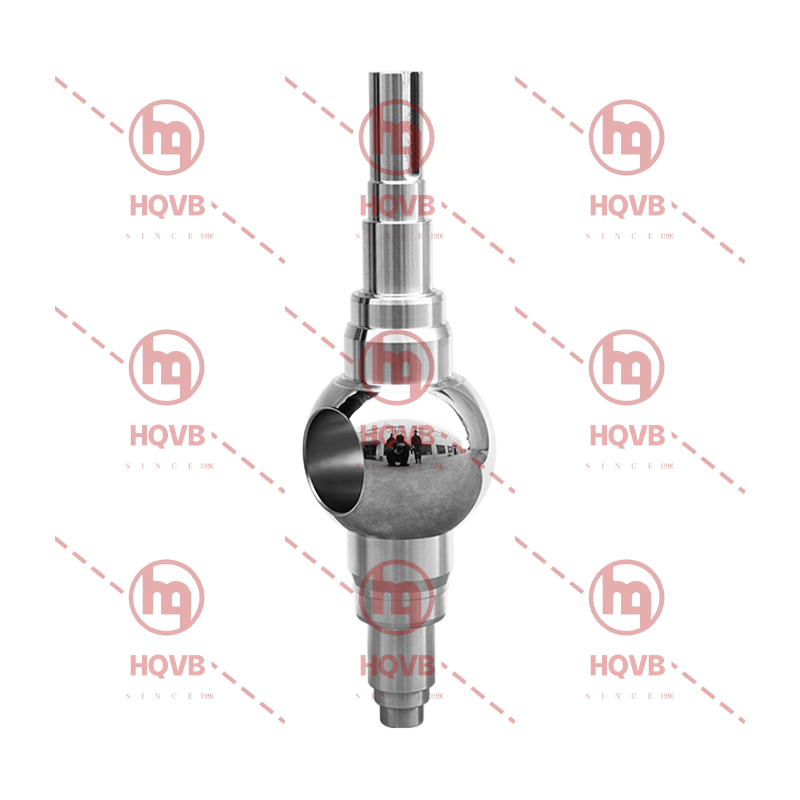

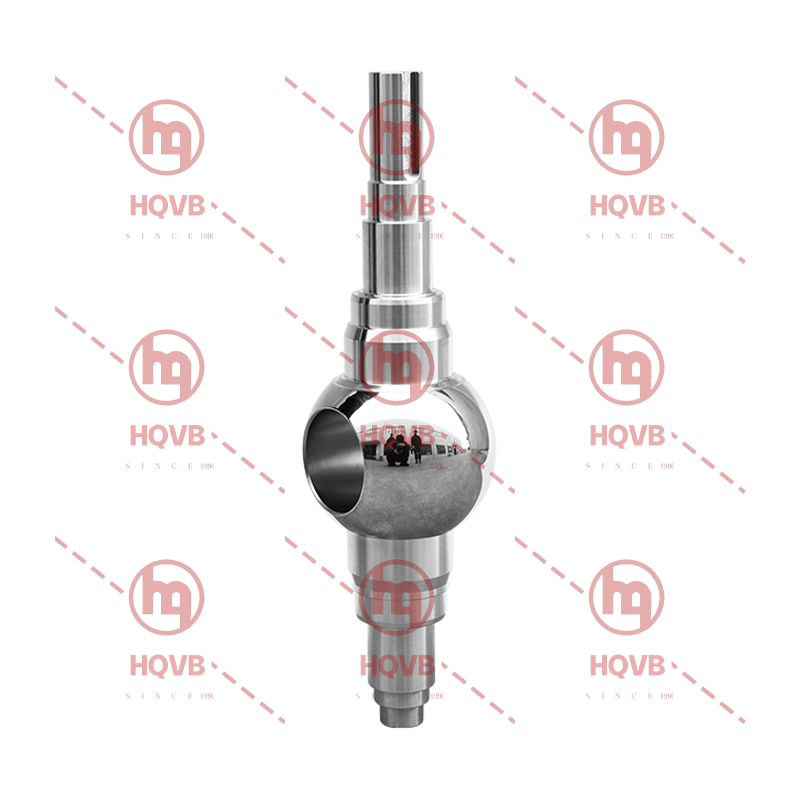

The ball valve ball is a critical component of the ball valve assembly. It is designed to control the flow of fluids by rotating a spherical element within the valve body. The ball valve ball is typically made from durable materials such as stainless steel, brass, or other corrosion-resistant alloys to ensure long-term reliability and performance in various industrial applications.

Material and Construction

The material selection for the ball valve ball is crucial as it directly impacts its durability and resistance to wear. Stainless steel is a popular choice due to its high strength and corrosion resistance. It can withstand harsh environments and is suitable for applications involving water, oil, and other chemicals. Brass is another common material used for ball valve balls, especially in applications where non-magnetic properties are required. The construction of the ball valve ball involves precision machining to achieve a smooth surface finish and tight tolerances. This ensures a complete seal when the valve is closed and allows for smooth and reliable operation.

Function and Operation

The primary function of the ball valve ball is to control the flow of fluids by rotating the ball within the valve body. The ball has a hole through its center, which aligns with the valve body's inlet and outlet when the valve is open. When the ball is rotated 90 degrees, the hole is perpendicular to the flow path, effectively blocking the fluid passage. This simple yet effective mechanism allows for quick and reliable on-off control of fluid flow. The ball valve ball operates smoothly due to its spherical shape, which reduces friction and wear during rotation. This makes it suitable for frequent operation without significant maintenance.

Applications

Ball valve balls are used in a wide range of applications across various industries. In the oil and gas industry, they are used in pipelines to control the flow of hydrocarbons. Their durability and resistance to corrosion make them ideal for such demanding environments. In the water treatment industry, ball valve balls are used in filtration systems and distribution networks to regulate water flow. They are also commonly used in chemical processing plants, where their resistance to chemical attack ensures long-term reliability.

Maintenance and Longevity

Proper maintenance is essential to ensure the longevity and performance of the ball valve ball. Regular inspection of the ball for signs of wear or corrosion is recommended. In case of minor wear, the ball can be polished to restore its surface finish. It is also important to keep the valve lubricated to reduce friction and wear during operation. Using the correct lubricant for the specific material of the ball valve ball is crucial to prevent chemical reactions that could lead to corrosion. With proper maintenance, a ball valve ball can last for many years, providing reliable service in its application.

The ball valve ball is a vital component in the operation of ball valves. Its durable construction, reliable performance, and versatility make it suitable for a wide range of industrial applications. By selecting the appropriate material and maintaining the ball valve ball properly, users can ensure long-term reliability and efficient fluid control. Whether in the oil and gas industry, water treatment plants, or chemical processing facilities, the ball valve ball remains a fundamental part of modern fluid control systems.