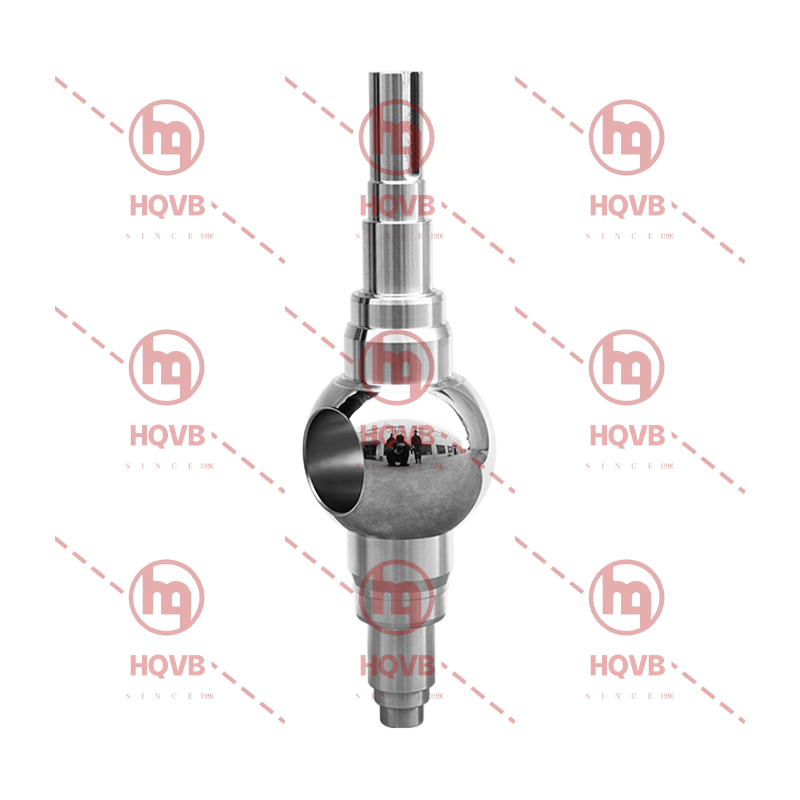

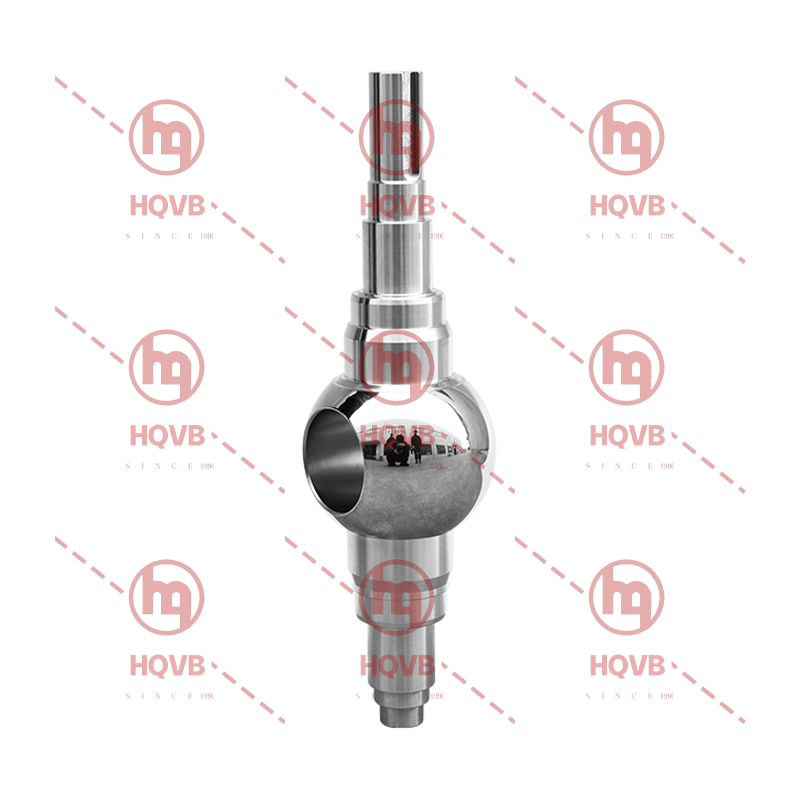

Hard seal ball valves are essential components in various industries, providing reliable shut-off and control of fluid flow. The ball, a critical element of these valves, plays a pivotal role in ensuring effective sealing and durability. This article delves into the materials and standard specifications of hard seal ball valve balls, highlighting their importance in valve performance.

Materials Used in Hard Seal Ball Valve Balls

The selection of materials for ball valve balls is crucial, as it directly influences the valve's performance, longevity, and suitability for specific applications. Common materials include:

-Stainless Steel: Renowned for its good corrosion resistance and strength, stainless steel is widely used in ball valve balls. It is suitable for a range of applications, including chemical processing and power generation.

-Carbon Steel: Offering good strength and wear resistance, carbon steel is often chosen for applications where the valve is exposed to abrasive substances or high pressure.

-Alloy Steels: Materials such as Hastelloy and Inconel provide few resistance to high temperatures and corrosive environments, making them ideal for demanding applications.

-Ceramic: Known for its hardness and wear resistance, ceramic is used in applications where durability is .

Standard Specifications

The specifications of hard seal ball valve balls are determined by factors such as size, pressure rating, temperature tolerance, and material composition. Key specifications include:

-Size: Ball valve balls are available in various sizes to accommodate different pipe diameters, typically ranging from 0.2 to 48 inches (5 to 1200 mm). The diameter of the ball can range from small sizes for mini valves to large sizes for high-capacity valves. The length and width of the ball are also designed according to the specific valve design and flow requirements.

-Pressure Rating: Valves are designed to withstand specific pressure levels, with some models capable of handling pressures up to 1000 bar, The pressure rating can vary from low-pressure applications to high-pressure systems, depending on the material and design of the ball.

-Temperature Range: The operating temperature of the ball is influenced by the material used. For instance, stainless steel balls can operate effectively at temperatures up to 750°F (400°C), while ceramic balls may withstand higher temperatures.

-Hardness: The hardness of the ball is critical for wear resistance. Materials like ceramic offer high hardness, enhancing the valve's durability in abrasive conditions.

Connection Type

The Hard Seal Ball Valve Ball can be connected to the valve body through various methods, such as threaded connection, flanged connection, or welding. The choice of connection type depends on the application requirements and the design of the valve.

Applications

Hard seal ball valve balls are utilized across various industries, including:

-Oil and Gas: For controlling the flow of hydrocarbons under high pressure and temperature conditions.

-Chemical Processing: Handling corrosive substances where material compatibility is essential.

-Power Generation: Regulating steam and water flow in power plants.

-Water Treatment: Managing the flow of water in treatment facilities.

The ball in a hard seal ball valve is a vital component that significantly impacts the valve's performance and longevity. Selecting the appropriate material and adhering to standard specifications are essential for ensuring best functionality in various industrial applications.