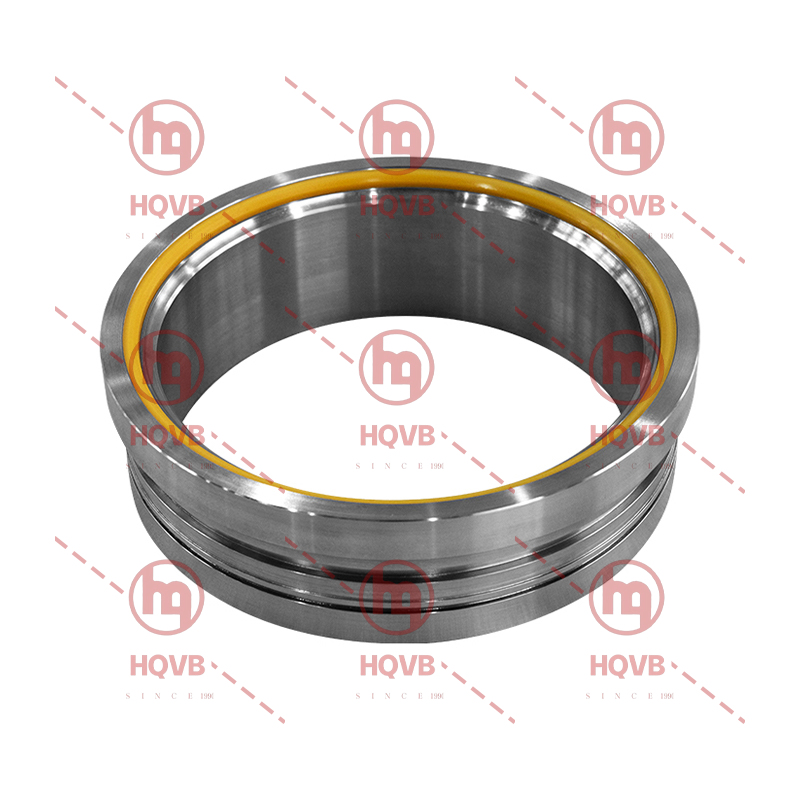

The ball valve seat is a crucial component in the structure of ball valves. It plays a vital role in ensuring the proper sealing and operation of the valve. This article will provide detailed information about the ball valve seat, including its features, materials, applications, and maintenance.

Features

The ball valve seat is designed to provide a tight seal when the valve is in the closed position. It is precision - machined to fit completely against the ball, creating a leak - free environment. The seats are available in a wide range of sizes, from NPS 1 to NPS 40 (DN25 - 1600), which makes them suitable for various industrial applications.

In terms of pressure ratings, the ball valve seat can handle pressures from Class 150 to Class 2500 (PN16 - 420). This wide pressure range ensures that the valve can be used in both low - pressure and high - pressure systems. The seats are also designed to withstand high - temperature conditions, making them ideal for use in industries such as oil and gas, chemical, and power generation.

Materials

The ball valve seat is typically made from high - quality materials that offer good corrosion resistance and durability. Common materials include stainless steel, carbon steel, and alloy steel. Stainless steel seats are ideal for applications where corrosion resistance is a key concern, such as in the food and beverage industry. Carbon steel seats are more cost - effective and are suitable for general - purpose applications. Alloy steel seats offer a good balance of strength and corrosion resistance, making them suitable for use in harsh environments.

Applications

The ball valve seat is used in a wide variety of applications. In the oil and gas industry, it is used in pipelines to control the flow of crude oil and natural gas. In the chemical industry, it is used to control the flow of corrosive chemicals. In the power generation industry, it is used in steam and water systems. The ball valve seat is also used in water treatment plants, HVAC systems, and many other industrial processes.

Maintenance

Proper maintenance of the ball valve seat is essential to ensure its long - term performance. Regular inspection and cleaning of the seat should be carried out to remove any debris or contaminants that may affect its sealing ability. Lubrication of the seat and the ball should also be done regularly to reduce friction and wear. In case of any damage or wear to the ball valve seat, it should be replaced immediately to prevent leaks and ensure the safe operation of the valve.

The ball valve seat is an important component of the ball valve, and its quality and performance directly affect the operation of the valve. With its wide range of sizes, pressure ratings, and materials, the ball valve seat can meet the needs of various industrial applications. Proper selection, installation, and maintenance of the ball valve seat can ensure the long - term reliable operation of the valve and contribute to the efficient operation of industrial processes. When choosing a ball valve seat, it is important to consider the specific requirements of the application, such as the fluid medium, pressure, and temperature, to select the great majority suitable product.