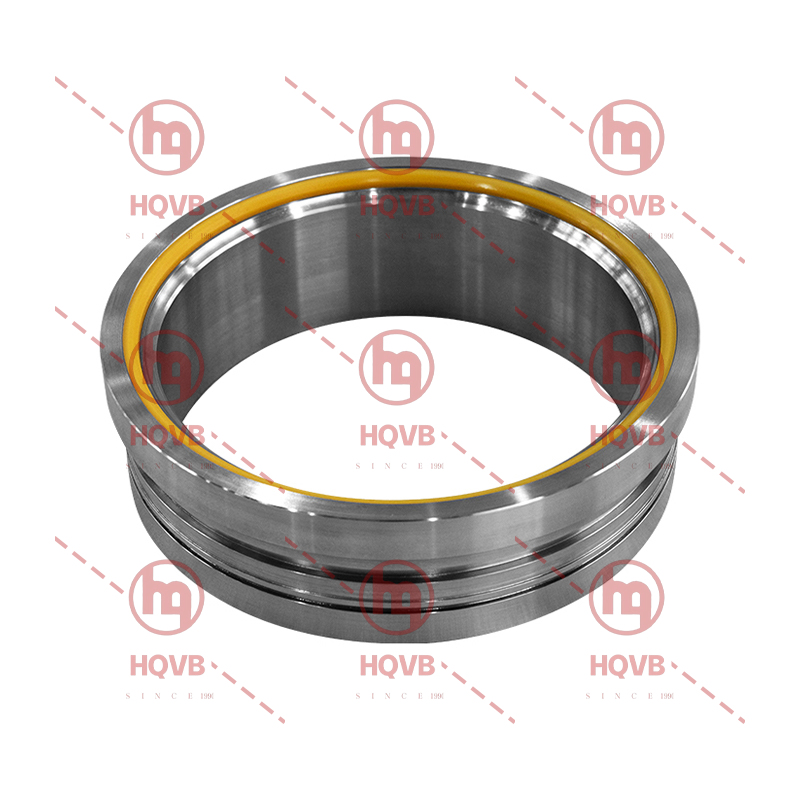

Soft sealing valve seats are crucial components in a wide range of industrial applications, offering efficient sealing solutions for various fluid and gas handling systems. Designed to ensure reliability and durability, these valve seats provide exceptional performance across diverse environments. Available in a broad range of materials and sizes, soft sealing valve seats are tailored to meet the demands of various pressure levels, temperatures, and fluid types.

High-Quality Materials for Exceptional Durability

Soft sealing valve seats are manufactured from a variety of premium materials that ensure long-lasting performance and resistance to wear and tear. The base materials used in the production of these valve seats include A105, LF2, F304, F316, F51, F53, Monel 400, Monel K500, INCOLOY 825, INCONEL 718, INCONEL 625, INCONEL 600, and HASTELLOY C-276. These materials are carefully selected for their superior strength, corrosion resistance, and ability to withstand high temperatures and pressures, ensuring that the valve seats can perform reliably in even the most demanding applications.

The inserts, made from high-performance polymers such as PTFE, PEEK, RPTFE, PPL, Delvon, PCTFE, TFM1600, POB, and UPE, provide excellent sealing properties. These materials are known for their chemical resistance, thermal stability, and low friction, ensuring an airtight seal while reducing the wear on valve components. By combining these high-quality materials, soft sealing valve seats can operate under extreme conditions with minimal maintenance requirements.

Wide Range of Sizes and Pressure Ratings

Soft sealing valve seats are available in sizes ranging from 1" to 64", allowing them to fit various valve types and applications. This extensive size range ensures that the valve seats can accommodate the needs of different industries, including oil and gas, power generation, water treatment, and chemical processing.

In addition to the wide range of sizes, these valve seats also come with pressure ratings from 150lb to 2500lb, providing flexibility to suit low to high-pressure systems. Whether used in low-pressure pipelines or high-pressure reactors, soft sealing valve seats maintain their performance and integrity under varying pressure conditions, offering reliable sealing capabilities.

Temperature Range for Diverse Applications

One of the key advantages of soft sealing valve seats is their ability to function across a broad temperature range, from -196°C to 250°C. This makes them suitable for use in both cryogenic and high-temperature environments, ensuring that they remain effective in diverse industrial applications. The ability to withstand such extreme temperatures is crucial for industries that deal with liquids and gases in different states, such as oil refineries, chemical plants, and LNG facilities.

Applications in Various Industries

Soft sealing valve seats find applications across a wide variety of industries, such as power generation, oil and gas, water treatment, food processing, and chemical manufacturing. Their versatile design makes them suitable for different valve types, including ball valves, gate valves, globe valves, and butterfly valves. These valve seats are especially beneficial in critical systems where leaks could lead to operational failures, safety hazards, or environmental damage.

Soft sealing valve seats are an essential component for ensuring the reliable operation of fluid and gas systems. With a broad range of materials, sizes, and pressure ratings, these valve seats offer versatile solutions for industrial applications. Their high-performance sealing capabilities, resistance to wear, and ability to function under extreme temperature and pressure conditions make them an ideal choice for a wide range of industries.